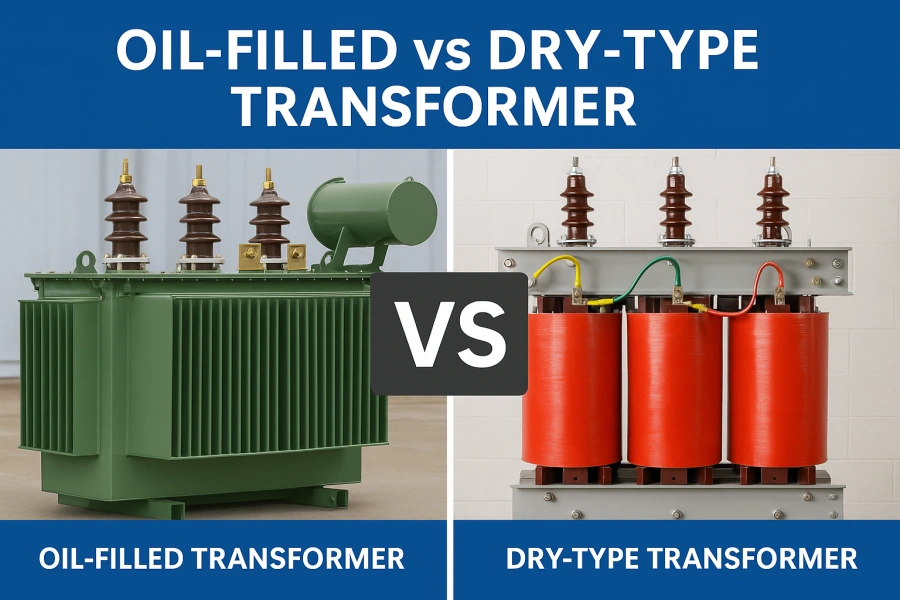

Introduction: Why Choosing the Right Transformer Type Matters

Transformers are vital components in any electrical system, stepping voltages up or down to meet power distribution needs. Choosing between an oil-filled and a dry-type transformer isn’t just a technical decision—it directly impacts safety, installation conditions, long-term maintenance, and overall project cost. Whether you’re designing for a commercial building, an industrial facility, or a utility grid, understanding the key differences is crucial.

What Is a Dry-Type Transformer?

A dry-type transformer is air-cooled and uses solid insulation rather than oil. The windings are typically cast in resin or sealed in vacuum pressure impregnation (VPI) systems to protect against moisture, dust, and contaminants.

Features:

Oil-free, air-cooled (natural or forced)

Typically installed indoors

Minimal environmental risk

Often quieter in operation

These are commonly used in commercial buildings, hospitals, schools, and any location where fire safety and environmental cleanliness are priorities.

Read More:What is Dry Type Transformer

What Is an Oil-Filled Transformer?

An oil-filled transformer uses mineral oil or biodegradable insulating fluids for both insulation and heat dissipation. The oil circulates through the core and windings, carrying heat to the surface where it is released.

Features:

Liquid-cooled with mineral oil or natural ester

Excellent for high-power or outdoor applications

Compact footprint for same capacity

Longer overload capability

These are often used in outdoor substations, heavy industrial zones, and energy projects like solar or wind farms.

Learn More:Comprehensive Guide to Types of Electrical Transformers and Their Applications

Pros and Cons: A Direct Comparison

🔷 Dry-Type Transformers

Pros:

No risk of oil leaks or contamination

Lower fire hazard

Suitable for indoor or enclosed spaces

Requires less frequent maintenance

Cons:

More expensive per kVA

Larger and heavier

Typically limited to <5 MVA

🔶 Oil-Filled Transformers

Pros:

Higher efficiency and better thermal performance

More compact and cost-effective for higher ratings

Ideal for harsh environments and outdoor use

Cons:

Requires routine oil quality testing and maintenance

Potential fire and environmental risk if leaks occur

Indoor use may require additional containment and ventilation

Ideal Application Scenarios

| Scenario | Recommended Type |

|---|---|

| Indoor installation | Dry-type |

| Commercial/residential buildings | Dry-type |

| High-power outdoor installations | Oil-filled |

| Substations or heavy industry | Oil-filled |

| Fire-sensitive or eco-sensitive areas | Dry-type |

| Remote/rural utility infrastructure | Oil-filled |

Cost, Size, and Maintenance Considerations

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Upfront Cost | Higher | Lower |

| Maintenance Needs | Low | Moderate (oil monitoring) |

| Size/Footprint | Larger | More compact |

| Cooling Method | Air | Oil circulation |

| Environmental Risk | Very low | Medium (oil handling) |

| Typical Power Range | Up to ~5 MVA | 25 kVA to 100+ MVA |

| Lifespan | 20–25 years | 25–30 years |

Which One Should You Choose?

When selecting the right transformer, consider:

Installation Location: Indoors or outdoors?

Safety Requirements: Are there strict fire codes or environmental policies?

Power Needs: Is your system under 5 MVA or does it require higher capacity?

Maintenance Capabilities: Can your team manage oil checks and containment?

Budget: Is upfront cost or long-term efficiency more important?

There’s no universal answer. Dry-type is ideal for safety-sensitive indoor settings, while oil-filled is better for high-power or utility-grade outdoor use.

Why Choose Our Transformers?

We manufacture and supply both oil-filled and dry-type transformers with global certifications including UL, ANSI, IEC, and CE. Our products are trusted by customers across North America, Europe, South America, and Asia, and we support OEM/ODM services, fast delivery, and competitive pricing.

Contact us today for expert guidance and a free quote tailored to your project.