Transformer R & D Service

EverNew Transformer stands as a beacon of excellence in the landscape of transformer manufacturing companies, boasting a rich legacy spanning over three decades. With an unwavering commitment to innovation and superior quality, we have honed an unmatched proficiency in the realm of transformer research and development services. Our expertise encompasses the entire spectrum of transformer design, development, and production, ensuring that each product surpasses industry benchmarks.

At EverNew Transformer, we push the boundaries of technology, mastering the intricacies of crafting ultra-high voltage transformers up to 500KV. From low-voltage distribution transformers to high-voltage transmission transformers, our comprehensive range of offerings caters to diverse requirements across industries. Our adaptability and agility enable us to customize solutions that precisely align with the unique needs of our clients, empowering them with reliable and efficient power solutions for every application.

Contact usOur R & D Capabilities

At EverNew Transformer, our prowess in research and development stands as the linchpin of our achievements and breakthroughs in the realm of transformer manufacturing companies. For over three decades, we have dedicated ourselves to pioneering advancements in transformer technology through relentless research and development endeavors. This journey is fueled by a dynamic and proficient team comprising engineers, researchers, and technologists who embody our commitment to innovation. Their collective passion and expertise drive us to continually push the boundaries of what is achievable in transformer technology, ensuring that EverNew Transformer remains at the forefront of the industry.

Advanced Design and Simulation:

Leveraging cutting-edge design software and simulation tools, we optimize transformer designs for maximum efficiency and reliability. Our engineers employ advanced modeling techniques to predict performance under various conditions, ensuring superior quality in our products.

Materials Research and Innovation:

Our ongoing research focuses on enhancing transformer materials and manufacturing techniques. By exploring new insulation, core, and conductor materials, we continually improve performance, efficiency, and sustainability in our transformers.

Prototyping, Testing, and Compliance:

With comprehensive prototyping and testing facilities, we rigorously validate designs to meet stringent quality standards. Our commitment to regulatory compliance ensures that our transformers adhere to safety, performance, and environmental regulations, providing customers with trusted and reliable solutions.

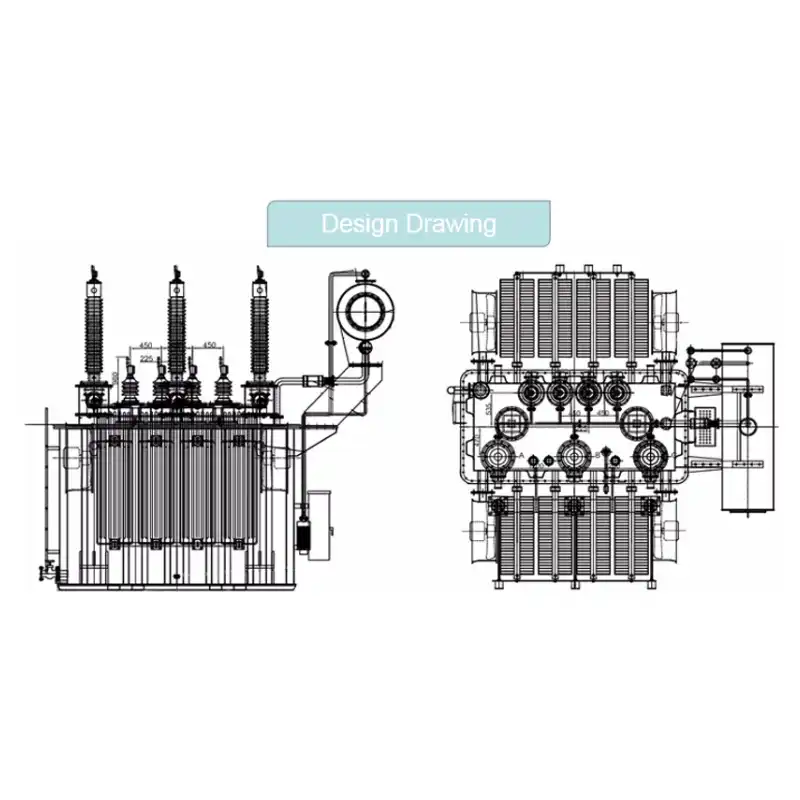

Design

Designing power transformers for Transformer Manufacturing Companies involves:

- Requirement Analysis: Understand customer needs and specs.

- Basic Design: Determine core parameters like materials and cooling methods.

- Detailed Design: Specify winding and core details.

- Magnetic Circuit Design: Ensure proper flux density.

- Winding Design: Optimize winding structures and parameters.

- Cooling System Design: Prevent overheating with effective cooling.

- Thermal Stability Analysis: Assess temperature rise under different loads.

- Electromagnetic Compatibility Design: Minimize interference.

- Performance Simulation and Testing: Validate design accuracy.

- Manufacturing and Production: Follow design specifications.

- Quality Control: Ensure adherence to standards.

- After-sales Service: Provide support for installation and maintenance.

Transformer Customization And Cases

EverNew Transformer provides customized solutions for fishery photovoltaic systems. Our offered 50MVA 110KV and 80MVA 35KV Transformers are designed keeping in mind high efficiency, reliability, safety and adaptability. They are made of high-quality materials and advanced processes to ensure stable operation and meet different photovoltaic system requirements. With their precise design and optimized structure, these transformers improve energy conversion efficiency, reduce costs, and promote environmental sustainability. Trust EverNew Transformer to provide reliable power conversion solutions for your photovoltaic power generation needs.

Changxin Transformer provided four customized 220kV transformers with capacities of 90/120/2×63MVA for Yuneng’s top factory. These four transformers are powerful, efficient, safe and reliable, and comply with strict international standards. Our transformers have multiple certifications of UL, cUL, CSA, SGS and meet IEEE, CSA, DOE and other standards. Using high-quality materials and world-leading technology, we ensure each transformer meets the factory’s unique requirements. Our commitment is to provide satisfactory products and services through solutions tailored to customer needs.

EverNew Transformer provides customized 127MVA 220KV transformers for energy storage power stations, with the following characteristics. The energy storage power station transformer adopts customized design to meet the special needs and high power density requirements of the energy storage system. Secondly, the response speed is fast, and the output power can be quickly adjusted when needed to adapt to the dynamic changes of the energy storage system. In addition, the energy conversion efficiency is higher, which can maximize energy utilization. Finally, the energy storage power station transformer is equipped with multiple safety protection functions to ensure the stable operation and safety of the energy storage system.

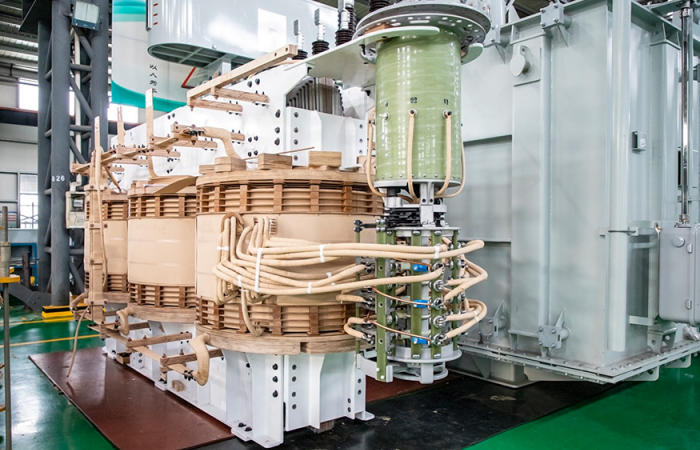

Manufacturing

At EverNew, as a distinguished player among transformer manufacturing companies, we are dedicated to crafting top-quality transformers that serve as pillars of support for power systems. Our production process integrates several crucial steps. We begin with core manufacturing, meticulously selecting materials and employing advanced processing techniques to ensure the core’s geometry and magnetic performance align with design requirements. Following this, in coil winding, we calculate turns, select wire diameters, and determine winding methods to achieve a compact coil structure with superior inter-turn insulation. Insulation treatment is another vital phase, where we utilize premium insulation materials to treat coils, ensuring the transformer’s safety and reliability during operation. Finally, in assembly, we seamlessly integrate cores and coils, conducting rigorous insulation tests and withstand tests to guarantee structural integrity and consistent electrical performance. Through these meticulous processes, EverNew delivers transformers that not only meet but exceed the highest quality standards and design specifications, offering customers unmatched reliability and peace of mind.

Full Capacity in Our factory Manufacturing Plant

3000+

Pad Mounted Transformer

As one of China’s top transformer manufacturing companies, EverNew not only offers customized production but also maintains a comprehensive stock of Pad Mounted Transformers ranging from 10KVA to 8MVA. This extensive inventory ensures prompt delivery to meet the diverse needs of our customers in the United States and Canada.

3000+

Pole Mounted Transformer

3000+

Dry Type Transformer

As a transformer manufacturing company, EverNew not only offers customized production but also maintains a warehouse stocked with various types of Dry Type Transformers, ranging from 50KVA to 3000KVA, with a maximum voltage of 35KV. These cast resin transformers are suitable for a variety of scenarios, ensuring versatility and reliability in power distribution.

Need Support?

We are 24/7/365 at your service!

EverNew has a professional transformer technical service team with rich experience and expertise in the transformer field, able to meet the diverse needs of customers. Our service scope covers transformer design, custom manufacturing, technical consulting, after-sales support, etc.

Want Support Now