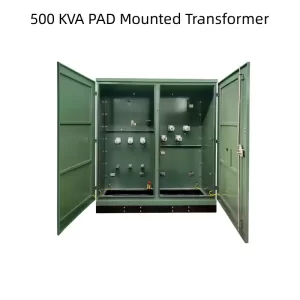

Evernew offers a full line of liquid filled 150 KVA three phase pad mounted distribution transformers that meet ANSI/IEEE standards. Our enclosed three-phase pad-mounted commercial transformers support voltage levels up to 34.5 kV and rated power capacities up to 20,000 kVA (ONAN). Designed for outdoor installation on concrete pads, they are ideal for underground power distribution in commercial, industrial, and institutional applications.

With over 30 years of design and manufacturing experience, Evernew is committed to providing efficient and reliable power solutions. Our transformers combine high quality materials with advanced engineering design systems to ensure superior performance and service life. We also provide rapid customization services to meet specific customer needs and requirements. Through innovation and careful design, our transformers perform well in a variety of complex environments, providing years of highly reliable service.

Learn more about capacity pad transformer: 500 Kva Pad Mounted Transformer

150 KVA Transformer Main Factory Test

Every 150 KVA three phase pad mounted transformer manufactured by Evernew undergoes a series of rigorous tests before it leaves the factory. These comprehensive tests are designed to verify that the transformer meets all technical specifications and industry standards. Our testing procedures ensure that each transformer not only meets the highest quality benchmarks, but also provides reliable performance and operational stability. By conducting these meticulous evaluations, Evernew guarantees that our transformers are both reliable and efficient, providing long-lasting service and maintaining high performance throughout their life cycle.The following are some of the regular test items for 150 KVA transformers:

- Temperature Rise Test: Measures the temperature increase of the transformer under full load conditions to ensure it operates within acceptable limits.

- Insulation Resistance Test: Evaluates the insulation resistance of windings and other components to ensure they are properly insulated.

- Power Factor Test: Assesses the power factor of the transformer insulation to determine its condition.

- Circuit Breaker Operation Test: Checks the operation and timing of circuit breakers used in conjunction with the transformer.

- Short-Circuit Impedance Test: Determines the impedance of the transformer under short-circuit conditions to verify its performance and stability.

- Transformer Turn Ratio Test: Verifies the turns ratio of each winding to ensure it matches design specifications.

- Partial Discharge Test: Detects and measures partial discharge activity within the transformer insulation system, which can indicate potential insulation problems.

- Thermal Imaging Test: Uses thermal imaging to detect hot spots and ensure uniform temperature distribution.

- Sweep Frequency Response Analysis: Measures the transformer’s frequency response to detect any mechanical or electrical issues.

- Dynamic Reactance Test: Assesses the dynamic response of the transformer to varying load conditions.

- Insulation Power Factor Test: Measures the power factor of the insulation system under different voltage levels to check for deterioration.

- Corrosion Testing: Evaluates potential corrosion in the transformer’s components, especially in harsh environments.

- Capacitance Measurement: Measures the capacitance of the transformer windings to ensure they are within design specifications.

- Neutral Grounding Resistor Test: Checks the resistance and performance of neutral grounding resistors used in the transformer system.

- Load Tap Changer (LTC) Functional Test: Assesses the operational performance and accuracy of the load tap changer.

- Bushing Power Factor Test: Measures the power factor of transformer bushings to ensure they are in good condition.

- Magnetic Flux Density Measurement: Evaluates the magnetic flux density in the core to ensure proper core operation.

- Frequency Response Analysis: Analyzes the transformer’s response to different frequencies to identify potential issues.

- Humidity and Insulation Strength Test: Measures the impact of humidity on insulation strength and performance.

- Vibration Analysis: Monitors vibrations to detect any mechanical issues or imbalances in the transformer.

Contact Evernew Transformer for more information on transformer testing

Finished product of 150 KVA transformer

We deliver 150 KVA 3 Phase pad mounted transformers of various voltage levels to many international customers every year.

150 KVA Transformer Tachnical Data

Typically, the dimensions and weight of a 150 KVA 12.47/0.415 KV three-phase bench-type transformer are as follows: dimensions are 1510 mm wide, 980 mm deep, 1530 mm high, and weight is 989 kg (excluding transformer oil). Designed to provide reliable performance in industrial, commercial, and rural utility applications, the 150 KVA transformers comply with stringent international standards such as ANSI, CSA, DOE, NEMA, and IEEE. They are equipped with environmentally friendly transformer oil and are suitable for installation in a variety of environmental conditions.

| Tachnical Data for Three Phase Pad Mounted Transformer | ||||||

|---|---|---|---|---|---|---|

| Rated Power (KVA) | Loss (W) | Dimension(mm) | Weight(kg) | |||

| No-load Loss (W) | On-load Loss (W) | W | D | H | ||

| 75KVA | 180 | 1250 | 1390 | 910 | 1430 | 645 |

| 150KVA | 280 | 2200 | 1510 | 980 | 1530 | 989 |

| 300KVA | 480 | 3650 | 1660 | 1080 | 1680 | 1415 |

| 500KVA | 680 | 5100 | 1810 | 1160 | 1790 | 1905 |

| 750KVA | 980 | 7500 | 2030 | 1300 | 2030 | 2755 |

| 1000KVA | 1150 | 10300 | 1651 | 1549 | 1854 | 3235 |

| 1500KVA | 1640 | 14500 | 2210 | 1470 | 2150 | 5835 |

| 2000KVA | 2160 | 20645 | 2380 | 1600 | 2220 | 6430 |

| 2500KVA | 2680 | 27786 | 3070 | 1650 | 2330 | 8865 |

| 3000KVA | 3300 | 30300 | 3260 | 1850 | 2460 | 11300 |

| 3750KVA | 4125 | 37875 | 4080 | 2060 | 2680 | 14400 |

Reviews

There are no reviews yet.