Power transformers are the most critical, high-value assets in any electrical grid or large industrial facility. When one fails, the clock starts ticking on massive financial loss and operational disruption. The question on every decision-maker’s mind is: “How long does it take to replace a power transformer?”

The simple answer is: It depends entirely on the size, complexity, and, most critically, the current global supply chain status. A residential unit swap can take hours, while a custom-engineered substation transformer replacement project can span several years.

This comprehensive guide breaks down the complex factors and phases that determine the true duration of a transformer replacement, offering essential insights for utility and industrial procurement professionals.

1. The Critical Distinction: Type and Scale (kVA/MVA)

The first step in estimating the timeline is identifying the transformer’s class, as this dictates the necessary logistics, equipment, and manufacturing lead time.

| Transformer Class | Capacity Range | Typical On-Site Execution Time | Total Time (w/ Procurement) | Key Challenge |

|---|---|---|---|---|

| Distribution (Small) | 10 kVA – 500 kVA | 4 – 8 Hours (Single Shift) | Days to Weeks | Site Access and Local Crew Availability. |

| Industrial/Medium Power | 1 MVA – 10 MVA | 1 – 3 Days | 2 – 6 Months | Securing Spares or Standard Designs. |

| Large Power Transformer (LPT) | 10 MVA – 800+ MVA | 3 Days – 3 Weeks | 18 Months – 4+ Years | Global Supply Chain and Custom Manufacturing. |

A. Distribution Transformers (Dismantling & Swapping)

These small to medium units are typically standardized and often kept as spare stock by utilities.

Example: A pole-mounted or small pad-mounted unit.

Speed Factor: Replacement is primarily a rigging and connection task, easily handled by a standard utility boom truck and small crew. The primary delay is often the crew’s travel time to the site.

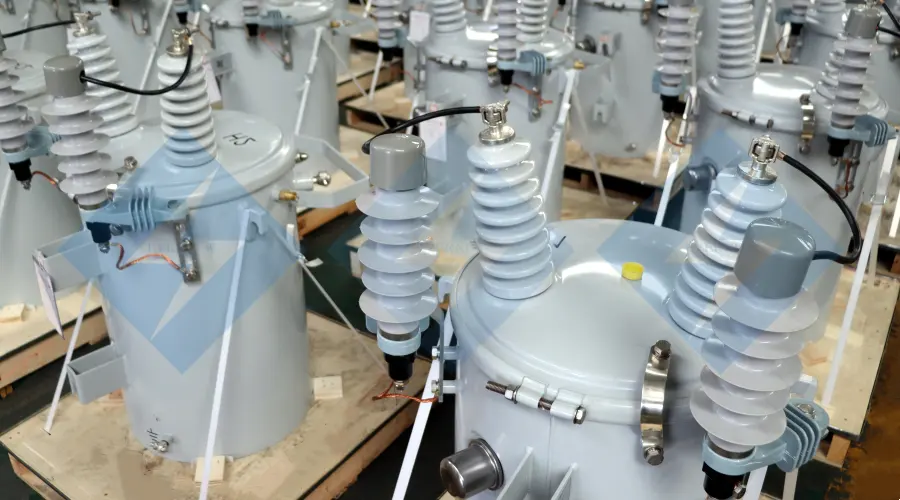

B. Large Power Transformers (LPTs) (Project & Commissioning)

LPTs handle high-voltage transmission and substation functions. They are custom-engineered to specific impedance, vector groups, and footprint requirements.

Speed Factor: This is not a simple swap; it is a complex heavy-lift engineering project. The time is dominated by specialized transport, precise civil alignment, vacuum oil processing, and rigorous testing.

Get More:Blown Transformer? Causes, Prevention, and Reliable Solutions from Evernew Transformer

About Evernew Transformer

As a global leader in power transformer manufacturing, Evernew Transformer is dedicated to providing highly reliable oil-immersed and dry-type transformer solutions to clients worldwide. We deeply understand the complexity and time sensitivity of transformer replacement projects, especially given current supply chain challenges. Whether you require a replacement unit meeting the latest efficiency standards or face an emergency outage demanding rapid response, our expert engineering team delivers customized technical support, optimized designs, and prompt delivery services. Evernew Transformer products are widely implemented in residential, commercial, and industrial applications across major global markets, including the United States, Canada, the United Kingdom, and Australia.

2. The Unseen Variable: The Procurement Crisis

For LPTs, the physical on-site work is the shortest part of the overall timeline. The overwhelming delay today is the manufacturing and delivery lead time.

Due to global material shortages (especially Grain-Oriented Electrical Steel (GOES)), limited global production capacity, and an aging grid demanding more replacements, lead times have dramatically increased:

| Component | Pre-2020 Lead Time | Current Average Lead Time | Impact on Failure |

|---|---|---|---|

| Single-Phase Pad-Mount (Distribution) | 4 – 6 Months | 12 – 18 Months | Prolonged residential/commercial outages. |

| Large Power Transformer (LPT) | 12 – 18 Months | 18 Months – 48+ Months | Critical system vulnerability; long-term grid outages. |

Key Takeaway for Buyers: If a non-standard LPT fails and no suitable spare is available, the facility or grid section relying on that transformer may face a minimum of 1.5 to 4 years of forced operational limitations or reliance on temporary bypass solutions. Proactive procurement is no longer optional—it is mandatory risk management.

3. Detailed Step-by-Step On-Site Timeline

Assuming the replacement transformer is ready and on-site, the execution still follows a rigorous, multi-day process to ensure safety and quality.

Phase 1: Preparation and Disconnection (4 Hours to 1 Day)

Fault Assessment & Outage Clearance: Utility/plant engineers confirm the fault, isolate the unit, and secure safety Lockout/Tagout (LOTO) clearances. (1-3 hours)

Oil Management (Oil-Immersed Units): Insulating oil must be safely drained and stored or disposed of. This is a critical environmental and logistical task for larger units. (3-8 hours)

Disconnection: All primary high-voltage bus connections, secondary cables, cooling system piping, and control/monitoring wiring are meticulously disconnected and tagged. (2-6 hours)

Phase 2: Removal and Site Preparation (8 Hours to 2 Days)

Rigging and Lifting: This requires heavy-duty cranes and precise coordination. The sheer mass of an LPT necessitates specialized heavy-lift planning. (4-12 hours)

Removal of Faulty Unit: The old transformer is lifted off its foundation and loaded onto a transport vehicle. (2-6 hours)

Foundation Inspection & Repair: The installation pad must be verified to be sound, level, and capable of supporting the new unit’s weight. Any necessary civil works (foundation repair, cable trenching) will immediately add days or weeks to the schedule.

Phase 3: Installation and Connection (1 Day to 5 Days)

New Transformer Positioning: The new unit is gently craned into its final position. Precision alignment is vital to match the high-voltage bus work. (4-12 hours)

Mechanical and Electrical Connections: Primary and secondary connections are secured, ensuring proper tension and grounding. This is a high-precision task involving certified high-voltage electricians. (1-2 days)

Auxiliary Systems Integration: Connection of cooling pumps, fans, On-Load Tap Changer (OLTC) motor drives, and fire suppression systems. (4-8 hours)

Vacuum Oil Filling (LPTs Only): The tank is pulled into a high vacuum to remove all moisture and air. New or processed oil is then slowly introduced under vacuum to maintain insulation integrity. This is often the longest step for oil-immersed units. (1-3 days of dedicated, continuous work)

Phase 4: Testing and Commissioning (1 Day to 3 Days)

This phase verifies operational safety and compliance. It is never skipped.

Standard Electrical Tests: Includes Winding Resistance, Transformer Turns Ratio (TTR), and Insulation Resistance (Megger) tests to confirm no damage occurred during transport or installation.

Advanced Diagnostic Tests: For LPTs, this includes Power Factor/Tan Delta Testing, and potentially Dissolved Gas Analysis (DGA) on the new oil to confirm the insulation system’s health.

Protection and Control Verification: Testing the trip circuits, relays, and SCADA monitoring points to ensure the unit is safely integrated into the wider control system.

Final Energization: Once all tests pass, the unit is cautiously energized and monitored under load.

Learn More:Power Transformer Diagram Guide for Buyers Selection, Installation, and Cost Insights

4. Mitigating Risks: Strategic Purchasing and Planning

To minimize your company’s exposure to long outages, procurement must shift from reactive to proactive risk management.

A. Establish a Spares Strategy

Identify your most critical LPTs and either maintain a suitable emergency spare unit or participate in a regional transformer-sharing reserve program. A spare unit eliminates the multi-year lead time risk.

B. Standardize Your Fleet

Where possible, select a standardized transformer design that allows for faster manufacturing and greater interchangeability between different sites, rather than demanding complex, one-off customizations.

C. Partner with Proven Manufacturers

Work with a manufacturer that demonstrates both deep engineering expertise and robust supply chain resilience. This ensures that when an order is placed, it moves through production efficiently.

Need a Reliable Replacement Solution?

At Evernew Transformer, we understand that transformer replacement is a capital project defined by urgent timelines and zero tolerance for error. As a leading manufacturer specializing in both oil-immersed and dry-type transformers, we offer:

Fast-Track Manufacturing Options: Leveraging our streamlined production capacity to deliver high-priority units faster than the industry standard.

Engineering Consultation: Expert guidance to ensure your replacement unit perfectly matches the required footprint and electrical specifications, minimizing on-site civil works.

Global Logistics Support: Specialized heavy-haul planning and shipping to sites worldwide, including the US, UK, Canada, and Australia.

Don’t let a supply chain crisis dictate your operational uptime.

📩 Contact Evernew Transformer today for a comprehensive technical consultation and a tailored quotation on your next transformer project, planned or emergency.