Enameled Flat Wire (Aluminum/Copper) Series

Discover Evernew Transformer’s high-quality enameled flat wire (copper & aluminum) for superior transformer windings, motors, generators, and reactors. Our rectangular magnet wire offers exceptional electrical and mechanical properties, meeting IEC standards for high-temperature winding applications. Get a quote for custom sizes and insulation grades.

Precision-Engineered Enameled Flat Wire for Superior Electrical Performance

As a leading component in advanced electrical systems, Enameled Flat Wire is an indispensable winding material for a vast array of equipment, including power and Substation transformers, generators, electric motors, reactors, and many other critical electrical devices. At Evernew Transformer, we pride ourselves on manufacturing premium-grade enameled flat wire designed to deliver unparalleled performance and reliability.

Our manufacturing process begins with high-purity oxygen-free copper rod or aluminum rod, precisely drawn through a rectangular die to achieve the desired dimensions. This conductor is then meticulously coated with multiple layers of high-performance insulating varnish, formulated for various temperature resistance levels. Following a controlled baking and curing process, the conductor and the durable insulation layer form a tight, robust bond, ensuring exceptional mechanical strength and superior electrical insulating properties. This meticulous engineering makes our rectangular enameled wire ideal for demanding applications requiring high fill factors and excellent heat dissipation.

Standards & Certifications

Our Enameled Flat Wire rigorously adheres to international quality and performance benchmarks, ensuring compatibility and reliability across global markets:

- GB/T7095-2008 / IEC

- IEC60317 Series

This compliance guarantees that our insulated magnet wire meets stringent industry specifications for your peace of mind.

Product Specifications: Copper and Aluminum Flat Wire Dimensions

Evernew Transformer offers a versatile range of enameled copper flat wire and enameled aluminum flat wire to suit diverse design requirements. If your project demands dimensions outside the specified ranges, please do not hesitate to contact us for custom manufacturing solutions.

Read More:Continuously Transposed Copper Conductors for High Power Transformers

Enameled Copper Flat Wire Specifications

| Dimension | Range | Unit |

|---|---|---|

| Narrow side (a) | 0.4 mm – 6 mm | mm |

| Wide side (b) | 2 mm – 16 mm | mm |

Enameled Aluminum Flat Wire Specifications

| Dimension | Range | Unit |

|---|---|---|

| Narrow side (a) | 0.8 mm – 5.6 mm | mm |

| Wide side (b) | 3 mm – 16 mm | mm |

For custom winding wire dimensions or specific cross-sectional areas, please connect with our sales and engineering team.

Specifications of Insulation Thickness (Film Build)

The thickness of the enamel coating (also known as the film build) is critical for the dielectric strength and overall insulation performance of the wire. We offer various insulation thickness grades to meet different voltage withstand and space factor requirements.

| Insulation Thickness Grade | Min. (mm) | Nominal (mm) | Max. (mm) |

|---|---|---|---|

| Grade 1 | 0.06 | 0.085 | 0.112 |

| Grade 2 | 0.12 | 0.145 | 0.17 |

Performance Parameters: High-Temperature Enameled Flat Wire for Demanding Applications

Our enameled flat winding wire is available with various insulation systems, each designed to perform optimally under specific thermal and environmental conditions. These high-performance magnet wires ensure the longevity and reliability of your electrical components.

| Product | Heat Resistance | Top Coat | Undercoat | Performance | Application | Thermal Shock |

|---|---|---|---|---|---|---|

| QZB-120 | 120℃ | Polyvinyl Acetal | Polyamide-Imide | Good resistance to transformer oil, excellent flexibility, adhesion, good hydrolysis resistance | Mainly used in oil-immersed transformers | 140℃ |

| QZB-130 | 130℃ | Polyester | Polyamide-Imide | Better oil heat resistance, hydrolysis resistance, strong adhesion, good flexibility | Dry or oil-immersed transformers, other electrical equipment | 155℃ |

| QZGB-155 | 155℃ | Modified Polyester | Polyamide-Imide | Good heat resistance, oil resistance, hydrolysis resistance | High and low voltage DC/AC motor electromagnetic coil, dry or oil transformers | 175℃ |

| QZJYB-200 | 180℃ | Polyester Imide | Polyamide-Imide | Very good heat resistance, oil resistance, chemical resistance | High and low voltage DC/AC motor electromagnetic coil, automotive coils | 200℃ |

| QXYB-220 | 200℃ | Polyester Imide | Polyamide-Imide | High heat resistance, strong chemical resistance, scratch resistance | High and low voltage DC/AC motor, rail transit coils | 220℃ |

| QXYB-240 | 220℃ | Polyimide | Polyamide-Imide | Excellent heat, chemical resistance, scratch resistance | High-temperature motor windings, transformers, sealed relay and electronic components | 240℃ |

| QY(F)-240 | 240℃ – 300℃ | Aromatic Polyimide | Polyamide-Imide | Highest heat resistance, solvent resistance, mechanical strength, breakdown voltage | Various high-end electrical equipment (aviation, mining, nuclear industry) | 300℃ |

Key Applications of Enameled Flat Wire

The unique properties of rectangular enameled wire – its excellent space factor, superior thermal conductivity, and robust insulation – make it the preferred choice for a wide range of demanding electrical applications:

- Transformers: Indispensable for power transformers, distribution transformers, and traction transformers, ensuring efficient energy conversion and long-term reliability.

- Motors: Used extensively in various electric motors, including high-performance industrial motors, compact EV motors for electric vehicles, and robust deep-sea motors operating under extreme conditions.

- Generators: Essential for the windings of electrical generators, from small-scale units to large power plant generators, ensuring efficient power generation.

- Reactors & Inductors: Critical for the construction of electrical reactors and inductors, where precise inductance and high current carrying capacity are required.

- High-Reliability Electrical Devices: Crucial for specialized and high-performance electrical components in critical sectors such as aviation (aerospace windings), nuclear power (radiation-resistant windings), and mining equipment (robust electrical coils), where extreme conditions and absolute reliability are paramount.

Why Choose Evernew Transformer for Your Enameled Flat Wire Needs?

At Evernew Transformer, we are committed to being one of China’s best power transformer manufacturers, and this commitment extends to the quality of our core components. Our enameled flat wires are engineered for superior performance, offering:

- Optimized Space Factor: Rectangular cross-sections allow for denser winding, maximizing power density and efficiency in your designs.

- Excellent Thermal Conductivity: The flat surface promotes efficient heat dissipation, contributing to cooler operation and extended component lifespan.

- High Dielectric Strength: Multi-layered insulation ensures robust electrical isolation, preventing breakdowns even under high voltage stress.

- Exceptional Mechanical Properties: Our wire resists abrasion, bending, and deformation during the winding process, ensuring manufacturing consistency.

- Customization: We offer a broad range of sizes and insulation grades, with the flexibility to develop custom enameled wire solutions for unique project requirements.

Partner with Evernew Transformer for reliable, high-quality enameled wire solutions that power your innovation.

Ready to enhance your electrical designs with premium enameled flat wire?

Contact Evernew Transformer today to discuss your specifications, request a quote, or learn more about how our advanced winding wire solutions can benefit your next project. Our experts are here to help you find the perfect fit!

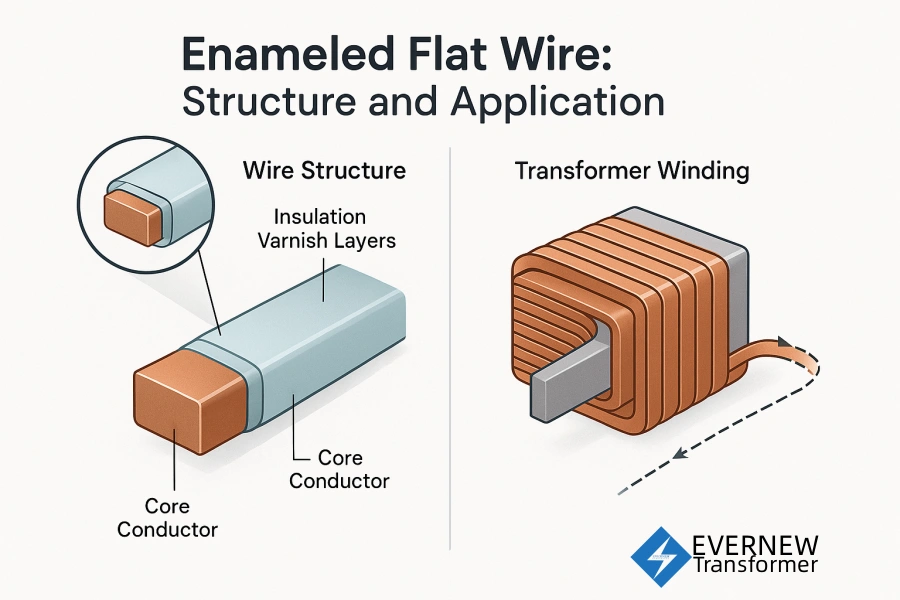

Structural Diagram Description for Enameled Flat Wire (For your graphic designer)

Enameled Flat Wire: Structure and Application

Reviews

There are no reviews yet.