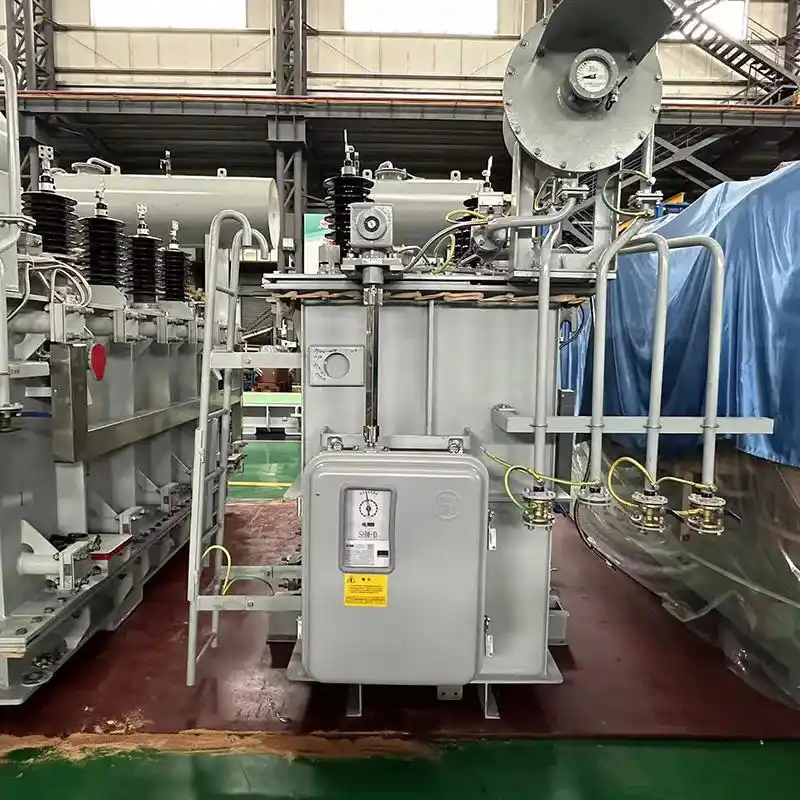

110kV three phase power transformer is an essential component in modern power systems, designed to facilitate efficient and reliable transmission and distribution of electricity. With a primary voltage of 110 kilovolts, this transformer is suitable for high voltage applications and is essential to step down the voltage to a level that industrial, commercial and residential consumers can use safely and efficiently, and the secondary voltage is 6.3kv, 10.5kv, 6.6kv, 11kv, 33kv, 69kv or customized. The three phase design enables balanced power distribution, thereby improving the stability and efficiency of the power grid.

EverNew aims to improve the performance of three phase oil immersed transformers, need the latest transformer information, contact us

Importance in High Voltage Transmission and Distribution

In the realm of high voltage transmission and distribution, the 110kV Three Phase Power Transformer plays a pivotal role. Here are key points highlighting its importance:

Efficient Power Transmission: By stepping up the voltage to 110kV, these transformers enable the transmission of electricity over long distances with minimal losses. High-voltage transmission reduces the current in the conductors, which reduces resistive losses (I²R losses), making the transmission process more efficient.

Voltage Regulation and Stability: 110kv transformers help maintain voltage levels within the desired range, ensuring that the end-users receive stable and reliable power. This is critical for preventing voltage fluctuations that can damage electrical equipment and disrupt services.

Integration with Power Grids: The 110kV voltage level is the standard for most national grids around the world, enabling seamless integration and interoperability with existing infrastructure. This standardization helps maintain consistency and reliability across the distribution grid.

Scalability and Flexibility: Designed to handle large amounts of power, 110kv transformers are scalable to meet the growing demands of urbanization and industrialization. They can be customized to specific voltage requirements, providing flexibility for a variety of applications.

Safety and Reliability: EverNew 110kV transformers are made of high-quality materials and comply with international standards such as IEC 60076, ANSI/IEEE C57, EN 60076, etc., to ensure safe operation of the power grid. Its solid structure and advanced insulation system minimize the risk of failure and extend the service life of the power infrastructure.

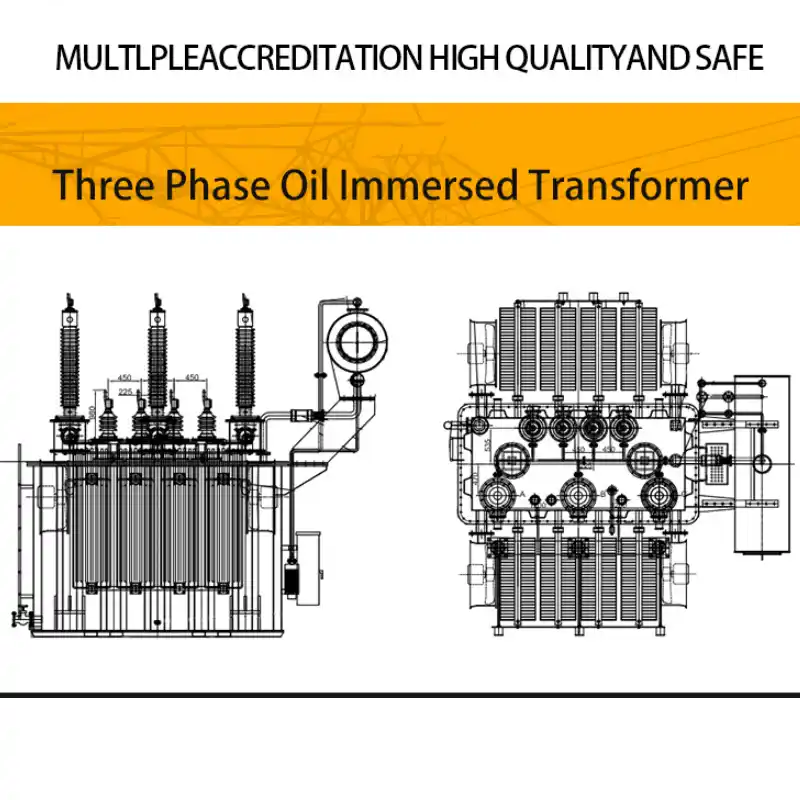

110kV Three phase Oil immersed Power Transformer High Voltage Construction and Materials

High-Quality Magnetic Core

The magnetic core of the 110kV three-phase oil-immersed power transformer is a crucial component that significantly impacts its efficiency and performance. Here are the key features of the magnetic core:

- Material: Made from high-permeability, low-loss silicon steel laminations, which reduce both hysteresis and eddy current losses.

- Design: Precision-engineered core with a step-lap joint design minimizes air gaps, ensuring optimal magnetic flux distribution and reducing core losses.

- Construction: The core is tightly assembled and securely clamped to minimize vibrations and noise, enhancing overall performance and longevity.

Superior Insulation Materials

High-quality insulation materials are essential for the safe and reliable operation of high-voltage transformers. The insulation system used in 110kV transformers includes:

- Material: Utilizes advanced cellulose-based paper and pressboard, as well as synthetic insulating materials that offer excellent dielectric properties.

- Thermal Stability: Designed to withstand high operating temperatures, maintaining structural integrity and dielectric strength over extended periods.

- Moisture Resistance: Insulation materials are treated to resist moisture absorption, preventing insulation degradation and ensuring long-term reliability.

Oil-Immersed Cooling System

Efficient cooling is vital to maintaining transformer performance and longevity. The oil-immersed cooling system in 110kV transformers includes:

- Insulating Oil: Filled with high-quality mineral oil that serves both as a cooling medium and an insulating agent, enhancing thermal conductivity and dielectric strength.

- Cooling Mechanisms: The system typically includes ONAN (Oil Natural Air Natural) cooling, where natural convection circulates the oil within the transformer. For higher capacity units, ONAF (Oil Natural Air Forced) cooling is employed, utilizing external fans to improve heat dissipation.

- Heat Dissipation: Equipped with radiators and cooling fins to maximize the surface area for heat exchange, ensuring efficient cooling even under heavy load conditions.

Durable Tank and Enclosures

The tank and enclosures of the 110kV transformer are designed to provide robust protection and maintain structural integrity under various environmental conditions:

- Material: Constructed from high-strength steel with anti-corrosion coatings to withstand harsh outdoor environments.

- Design: The tank features a sealed design to prevent the ingress of moisture and contaminants. It includes conservators or oil expansion tanks to accommodate thermal expansion and contraction of the insulating oil.

- Protection: Fitted with protective devices such as pressure relief valves, Buchholz relays, and oil level indicators to monitor and maintain safe operating conditions.

To learn more about EverNew 110kV three-phase oil-immersed power transformer high voltage materials, contact us

110kV Three Phase Power Transformer High Voltage Applications

Transmission Systems

110kV three phase power transformer play a crucial role in high voltage transmission systems. They step up the output voltage from power plants to 110kV, reducing energy loss over long distances. This efficient voltage conversion decreases the current, thereby reducing resistive losses (I²R losses) in the conductors, ensuring that more electrical power reaches its destination.

- Key Advantages: Efficient energy transmission, reduced transmission losses, improved overall system efficiency.

- Application Scenarios: Long-distance power transmission lines, large transmission networks.

Substations

110kV three phase power transformers are the core components of step-down substations. These transformers convert high voltage electrical energy into medium and low voltage electrical energy suitable for distribution and use. Substations are usually located between power plants and distribution networks, ensuring that electricity is delivered to end users at the appropriate voltage level.

- Key Advantages: Efficient voltage conversion, ensuring power system stability, supporting large-scale power distribution.

- Application Scenarios: Power plants, urban and regional substations.

Industrial Facilities

In large industrial facilities, 110kV three phase power transformers provide a stable power supply to meet the needs of high load and continuous operation. Industrial transformers convert high-voltage electrical energy into the operating voltage required by industrial equipment, ensuring the continuity of the production process and the safe operation of machinery.

- Key Advantages: Providing stable and reliable power, supporting high load operations, enhancing industrial production efficiency.

- Application Scenarios: Large manufacturing plants, chemical plants, metallurgical plants.

Urban and Rural Power Grids

110kV three phase power transformers are widely used in urban and rural power grids, ensuring reliable power supply to residential and commercial users. By converting voltage levels, they support the efficient operation of the power grid, meeting the electrical needs of different areas, and improving the quality of life and economic development.

- Key Advantages: Supporting stable grid operation, providing reliable power supply, adapting to various environmental conditions.

- Application Scenarios: Urban grids, rural grids, commercial and residential areas.

To learn more about the applications of 110kV three phase power transformers in transmission systems, substations, industrial facilities, urban and rural power grids, contact us. EverNew is committed to providing you with customized application solutions.

110kv oil immersed power transformer protection systems

The protection system of oil-immersed power transformers is a key component to ensure the safety and reliability of the transformer in normal operation and abnormal conditions. The following are the common protection systems and their functions of 110kv oil-immersed power transformers

Oil Temperature Monitoring System:Oil-immersed transformers are typically equipped with oil temperature monitoring devices to monitor the temperature of the transformer oil. High temperatures may indicate abnormal operation or faults in the transformer. Therefore, the oil temperature monitoring system can issue timely alarms to take appropriate measures to prevent equipment damage or accidents.

Oil Level Monitoring System:The oil level monitoring system is used to monitor the oil level in the transformer oil tank. Low or high oil levels may cause unstable operation or equipment damage. Hence, the oil level monitoring system can help operators promptly detect and address these issues.

Pressure Protection System:The pressure protection system monitors the oil pressure inside the transformer oil tank and triggers protective actions in case of abnormal oil pressure. For instance, excessively high oil pressure may lead to equipment leakage or damage. Therefore, the pressure protection system will cut off power or trigger alarms promptly to protect the transformer and surrounding equipment.

Gas Monitoring System:Oil-immersed transformers are typically equipped with gas monitoring systems to monitor the gas content in the oil, especially combustible gases. Changes in gas concentrations may indicate faults or abnormal conditions inside the transformer. Hence, the gas monitoring system can help promptly detect and address these issues to prevent equipment damage or accidents.

Overcurrent Protection System:The overcurrent protection system monitors the current flowing through the transformer and triggers protective actions when the current exceeds a set threshold. This protection system effectively protects the transformer from the effects of overloads or short circuits, ensuring the safe operation of the equipment.

The protection system of oil-immersed power transformers covers many aspects, including oil temperature monitoring, oil level monitoring, pressure protection, gas monitoring and overcurrent protection to ensure the normal operation of the transformer. Contact us and EverNew will show you more about the transformer protection function.

Maintenance of 110 KV Oil Immersed Power Transformers: Key Practices

Oil-immersed power transformers require diligent maintenance to ensure optimal performance and longevity. While dry-type transformers may have their advantages, proper maintenance of oil-immersed transformers offers unique benefits. Below, we explore essential maintenance methods for oil-immersed transformers:

1. Moisture Prevention:Moisture can compromise the insulation properties of transformers. Hence, employing moisture prevention measures is crucial. Upon arrival at the site, transformers should be equipped with dehumidifiers to safeguard internal components. Monitoring the silica gel within dehumidifiers and replacing it if moisture is detected is essential for transformer protection.

2. Oil Leakage Prevention:Oil-immersed transformers rely on tight sealing to prevent oil leakage. Loose bolts due to vibration can compromise these seals. During maintenance, ensuring all bolts are properly tightened and inspecting rubber components for cracks or deformations is vital. When replacing rubber parts, ensuring compatibility and maintaining seal cleanliness are imperative.

3. Reduced Storage Time:Minimizing the duration of transformer storage before delivery is crucial. Transformers are susceptible to moisture during storage, necessitating a well-planned storage strategy to minimize exposure. Additionally, draining accumulated water from the oil pillow before operations such as lifting, repairs, or refilling is essential to prevent contamination of the oil tank.

4. Oil Replacement and Bushing Treatment:Extended idle periods or prolonged operation can lead to insulation degradation or oil deterioration within transformers, requiring oil replacement and bushing treatment.Oil replacement involves draining the old oil, cleaning the tank, and refilling it with fresh oil. Additionally, replacing all oil-resistant rubber seals is necessary before conducting tests and commissioning the transformer. For larger transformers, vacuum drying by local power utilities is recommended to ensure proper insulation drying and prevent aging.

Understanding and following these maintenance specifications can improve the reliability and service life of oil-immersed power transformers, ensuring uninterrupted power supply and optimal performance. Contact EverNew and let our service experts provide you with more advice.

Technical Characteristics of 110kv High Voltage Special Oil lmmersed Power Transformer

| Place of Origin | Jiangsu, China |

|---|---|

| Brand Name | EverNew |

| Coil Number | 2 winding |

| Use | power |

| Output Voltage | or others, 6.3kv, 10.5kv, 6.6kv, 11kv, 33kv, 69kv |

| Input Voltage | or others, 63kv, 66kv, 69kv, 110kv, 132kv, 138kv, 220kv |

| Usage | Power |

| Phase | Three |

| Coil Structure | TOROIDAL/ PIE COIL |

| Model Number | S11 |

| Coil Number | 2 winding |

| Tap Changer | OLTC |

| Frequency | 50Hz/60Hz |

| Winding material | Copper |

| Certification | ISO9001:2008 CE |

| Vector group | Dyn11,Yyn0,Yzn11 |

| Rated capacity | 30 to 1600kva |

| Standard | IEC60076 |

| Cooling Method | ONAN ONAF |

| Operating temperature | 40 To+180 |

| keywords | oil immersed transformer |

| Warranty | 2 Years |

Voltage Level of 110kv High Voltage Special Oil lmmersed Power Transformer

| Rated Capacity (kva) | HV (kV) | HV Tapping Ranges | LV (kV) | Vector-group | Short -Circuit Impendance | No-load Loss | On-load Loss | No-load Current (%) |

|---|---|---|---|---|---|---|---|---|

| 6300 | 63 | ±8×1.25% or others | 6.3 6.6 10.5 11 33 69 or others | YNd11 YNyn0 or otheres | 10-14 | 9.4 | 34 | 0.63 |

| 8000 | 11.2 | 40.4 | 0.63 | |||||

| 10000 | 13.1 | 47.6 | 0.75 | |||||

| 12500 | 15.4 | 56.5 | 0.53 | |||||

| 16000 | 18.5 | 69.5 | 0.49 | |||||

| 20000 | 21.8 | 84.2 | 0.49 | |||||

| 25000 | 25.6 | 99.5 | 0.4 | |||||

| 31500 | 30.4 | 120 | 0.4 | |||||

| 40000 | 36.2 | 140.3 | 0.39 | |||||

| 50000 | 42.6 | 174.3 | 0.39 | |||||

| 63000 | 52 | 210 | 0.39 | |||||

| 75000 | 60 | 238 | 0.49 | |||||

| 90000 | 69 | 274 | 0.49 | |||||

| 120000 | 85 | 328 | 0.46 | |||||

| 150000 | 101 | 385 | 0.42 | |||||

| 160000 | 105 | 404 | 0.42 | |||||

| 180000 | 115 | 436 | 0.42 | |||||

| 240000 | 144 | 539 | 0.4 |

Reviews

There are no reviews yet.