High voltage transformers are essential in electrical power systems, allowing the efficient transmission of electricity over long distances. These transformers either step up or step down voltage levels, enabling power to be transported from power plants to end users with minimal loss. In this blog, we’ll dive into the different types of high voltage transformers, their applications, and why Evernew Transformer, one of China’s leading transformer manufacturers, is the ideal choice for high voltage transformer needs, offering custom solutions, fast delivery, and competitive pricing.

What is a High Voltage Transformer?

A high voltage transformer is a device designed to convert electrical energy from one voltage level to another, typically in the range of 110 kV to 500 kV. These transformers play a critical role in power transmission systems, reducing energy loss over long distances and ensuring electricity reaches homes, businesses, and industries at usable voltage levels. For example, power plants generate electricity at high voltage, and transformers step up or step down the voltage before transmission or distribution to minimize losses and maintain safety.

How Does a High Voltage Transformer Work?

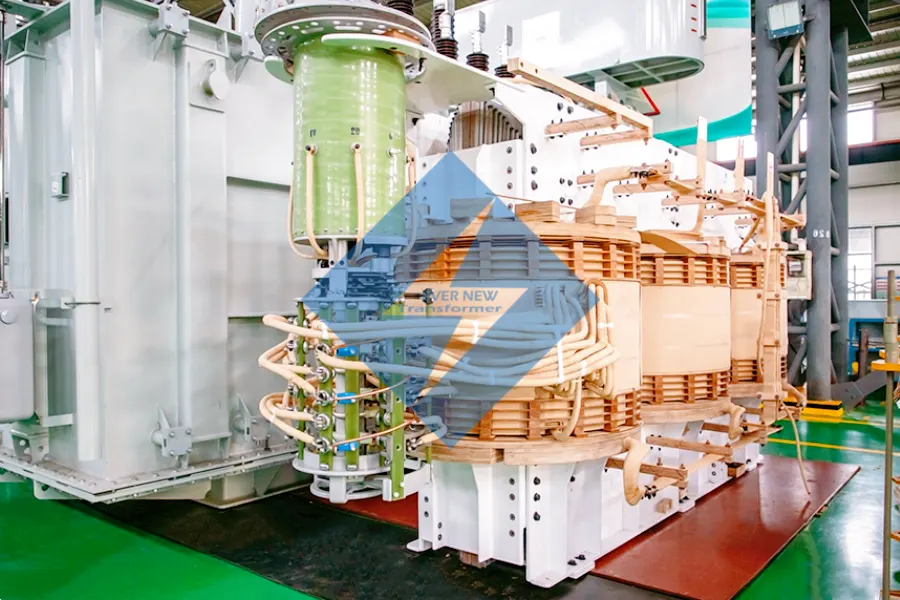

The working principle of a high voltage transformer is based on electromagnetic induction. It consists of a primary winding and a secondary winding, both wound around a core that forms a closed loop. When an alternating voltage is applied to the primary winding, it generates a fluctuating magnetic flux in the core. Due to the different number of turns in the primary and secondary windings, the fluctuating magnetic flux induces an electromotive force (EMF) in both windings. The magnitude of the induced EMF in the primary and secondary windings differs, which results in voltage transformation. The more turns in the coil, the higher the output voltage. As a result, high voltage transformers tend to be larger in size.

Learn more:Dry Type Transformer

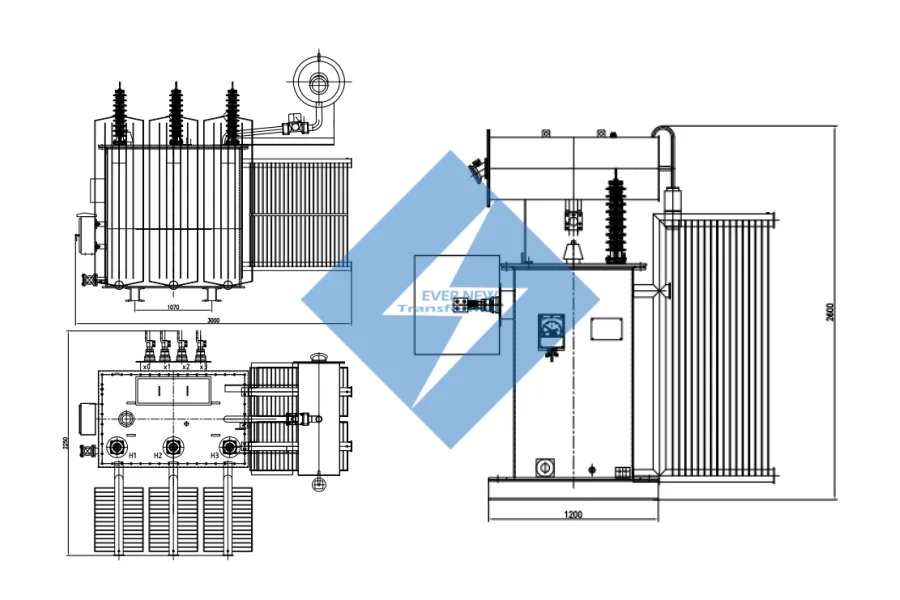

How to Manufacture a High Voltage Transformer?

Wind the Coils:Wind the primary and secondary coils with copper or aluminum wire.

Fabricate the Core:Construct the core from laminated steel sheets.

Assemble Coils and Core:Place the coils on the core and dry them to remove moisture.

Mount Components in the Tank:Install the core and coils into the tank and fill with insulating oil.

Vacuum and Oil Filling:Apply a vacuum and inject mineral or plant-based oil for insulation.

Seal the Tank:Seal the transformer tank to prevent contamination.

Electrical Testing:Test for proper functionality and insulation resistance.

Cooling System:Install a cooling system for heat management.

Factory Testing:Conduct final tests for performance and safety.

Packaging and Delivery:Package and ship the transformer after successful testing.

Try for free:110kv High Voltage Special Oil Immersed Power Transformer

Types of High Voltage Transformers

High voltage transformers come in various forms to meet specific needs in the electrical power industry. Here are some of the most commonly used types:

1. High Voltage Power Transformer

High voltage power transformers are used in power plants and substations to step up or step down voltage for long-distance transmission and distribution. These transformers are essential for large-scale power transmission and are designed to handle voltages from 110 kV to 500 kV and beyond. For instance, a 500 kV transformer can carry large amounts of electrical power over hundreds of kilometers, significantly reducing transmission losses.

2. High Voltage Distribution Transformer

These transformers step down high voltage to lower levels for residential, commercial, and industrial use. A distribution transformer can typically handle voltages in the range of 11 kV to 33 kV, making it an ideal choice for local electricity distribution. According to the International Energy Agency (IEA), distribution transformers account for approximately 50% of the total energy loss in power distribution systems, underscoring their importance in energy efficiency.

Learn More:220 kv 230kv High Voltage Special Oil Immersed Power Transformer

3. High Voltage Dry Type Transformer

Unlike oil immersed transformers, high voltage dry type transformers use air as a cooling medium, making them safer in environments where fire risk is a concern. They are commonly used in indoor installations, such as office buildings and factories. The global market for dry-type transformers is growing rapidly, with projections estimating it will reach USD 3.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 7.6%.

4. High Voltage Step-Up Transformer

A step-up transformer is used to increase the voltage for efficient transmission over long distances. For instance, in a typical power plant, a 220 kV step-up transformer boosts the voltage from the generator’s output level (e.g., 13.8 kV) to 220 kV or higher, optimizing transmission efficiency. This allows electricity to travel hundreds of kilometers with minimal energy loss.

5. High Voltage Step-Down Transformer

On the other hand, step-down transformers are used to lower the voltage to a safer level for end users. For example, a 33 kV step-down transformer will reduce the voltage to 11 kV or 440 V for use in local grids and homes.

Read More:Pad Mounted Transformer

Key Features of High Voltage Transformers

1. Winding Construction

The winding is the heart of any transformer. It determines the efficiency, capacity, and thermal performance of the transformer. For high voltage transformers, copper or aluminum windings are typically used due to their high conductivity and efficiency. A 500 kV transformer might have copper windings to handle the immense electrical load, ensuring the transformer can operate at high capacities for extended periods.

2. Transformer Sizes

High voltage transformers come in a wide range of sizes to match various applications. For instance, a 500 kVA transformer might be used for smaller industrial applications, while large power plants or substations may require transformers with ratings as high as 500 MVA. Transformer sizes are directly tied to the electrical load and the transmission distance; larger transformers are used for long-distance, high-capacity power transmission.

3. Transformer Price

The cost of a high voltage transformer can vary depending on factors like voltage rating, power capacity, and whether the transformer is custom-made. On average, the price for a high voltage transformer can range from USD 20,000 for smaller models to USD 1 million for large, custom-built units capable of handling 500 kV or more. Choosing the right manufacturer can significantly impact both the price and quality of the transformer.

Reading more about:Substation Transformer

Applications of High Voltage Transformers

High voltage transformers are used in a wide variety of applications across different industries:

Power Plants: In power plants, high voltage power transformers step up the voltage from the generator to a level suitable for transmission. The 220 kV and 500 kV power transformers are the most commonly used in power generation.

Substations: High voltage transformers are essential for stepping down the voltage from transmission levels to lower levels, making it safe for local distribution networks.

Industrial Applications: Industries with heavy machinery and equipment often require high voltage transformers to manage large amounts of electricity, ensuring operational continuity.

Renewable Energy: With the growing emphasis on renewable energy, high voltage transformers are becoming integral in integrating wind and solar power into national grids. These transformers handle the fluctuations in power output from renewable sources and maintain grid stability.

Learn More:What is a power plant transformer

Several manufacturers specialize in high voltage transformers, each offering different levels of quality, customization, and delivery time. Some well-known manufacturers include ABB, Siemens, and General Electric (GE). However, for clients seeking competitive pricing, quick delivery, and custom solutions, Evernew Transformer has emerged as one of the leading suppliers globally.

Why Choose Evernew Transformer for High Voltage Transformers?

Evernew Transformer is a top transformer manufacturer based in China, specializing in the production of high voltage transformers up to 500 kV. Here’s why Evernew Transformer stands out as a reliable partner for your transformer needs:

1. Custom Solutions

Evernew offers custom high voltage transformers, ensuring that each transformer meets the specific requirements of the client, whether it’s a step-up transformer, distribution transformer, or a high voltage dry type transformer. Custom solutions allow for better performance and cost-efficiency.

2. Wide Range of Voltage Ratings

Evernew’s product lineup covers a broad range of voltage ratings, from 110 kV to 500 kV, ensuring that customers can find the right transformer for any application.

3. Fast Delivery

Evernew Transformer excels at delivering high-quality products quickly. Their fast delivery times ensure that projects stay on schedule, which is critical for industries relying on timely installations.

4. Competitive Pricing

Evernew offers affordable prices without compromising on quality. Whether you need a high voltage transformer for a power plant or an oil-immersed transformer for an industrial project, Evernew ensures competitive prices tailored to client budgets.

5. Global Expertise

Evernew has extensive experience serving customers worldwide, including countries in North America, Europe, and Asia. With a track record of providing reliable, high-quality transformers, Evernew is a trusted supplier to meet global demand.

Read More:Comprehensive Guide to Pad Mount Transformer

Conclusion

High voltage transformers are critical for ensuring efficient power transmission and distribution. Whether you need a high voltage step-up transformer, distribution transformer, or dry-type transformer, choosing the right manufacturer is essential for reliable operation and cost-effective solutions.

Evernew Transformer, one of China’s top transformer manufacturers, offers custom-made solutions for high voltage transformers up to 500 kV. With fast delivery, competitive prices, and a strong reputation for quality, Evernew is your trusted partner for high voltage transformer needs.

Learn More:63kv 66kv 69kv High Voltage Power Transformer Manufacturer