Professional Electrical Transformer Manufacturers

EverNew Transformers is one of the top professional Electrical Transformer Manufacturers and suppliers in China. We deliver more than 10,000 transformers of various types to the world every year. Our products cover Pad Mounted Transformers, Power Transformers, Distribution Transformers, Pole Mounted Transformers, Dry Type Transformers, Substation Transformers, and beyond. Provide you with professional transformer solutions.

Top R&D Capabilities: With over 30 years of expertise, EverNew’s skilled engineering team designs transformers to meet international standards such as IEC, IEEE/ANSI, and CSA. We hold numerous patents and collaborate with global suppliers to ensure top-tier quality.

Company Certifications: As a trusted Electrical Transformer Manufacturers, EverNew is certified with ISO 9001:2008, UL/CUL, CSA, CESI, CNAS, SGS, GOST and CE. These certifications underline our commitment to quality and compliance with global safety and performance standards.

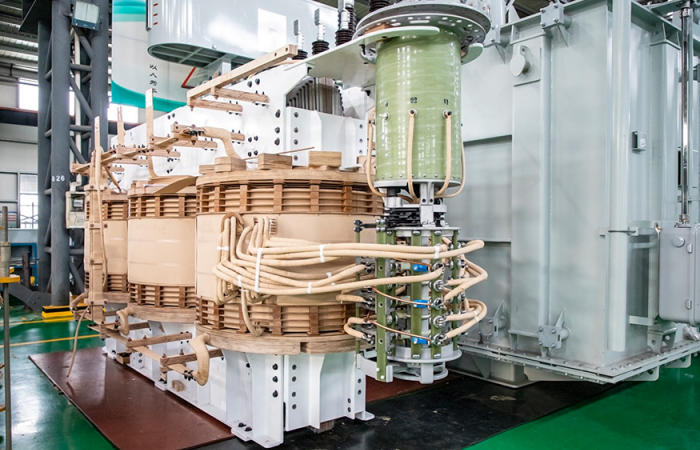

Professional Factory: As China’s leading Electrical Transformer Manufacturers, operates a factory covering over 500 acres. It produces various transformers and key components like enameled wire, insulating paper, and enclosures.

Get In TouchTypes of Transformers We Made

Power Transformer

China’s top Power Electrical Transformer Manufacturers, with 110KV, 220KV and 500KV ultra high voltage oil immersed power transformers, with a maximum capacity of 1200 MVA

Get a free quoteDistribution Transformer

Best 6 KV – 44.5 KV Distribution Electrical Transformer Manufacturers,efficiently regulate electrical voltage for safe transmission across local power distribution networks.

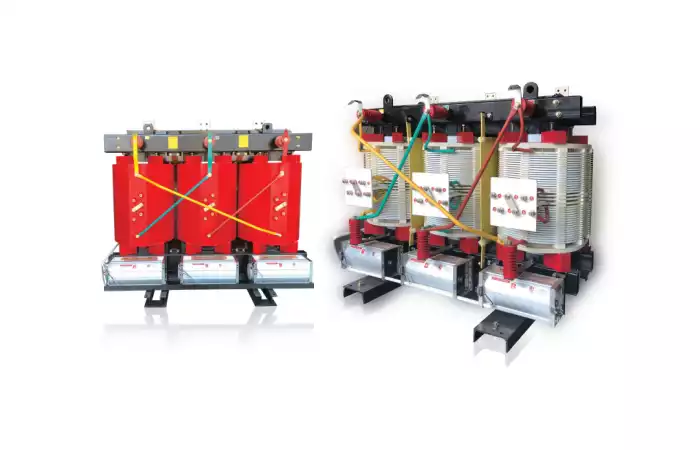

Get a free quoteDry Type Transformer

25 KVA – 20000 KVA Dry Type Electrical Transformer Manufacturers,Our cast resin transformers, which have garnered multiple patents, offer exceptional performance and reliability

Get a free quotePole Mounted Transformer

10 KVA -500 KVA Pole Mounted Electrical Transformer Manufacturers efficiently distribute high voltage power to residential and commercial areas, installed on utility poles to save space.

Get a free quoteSubstation Transformer

11KV – 69 KV Substation Electrical Transformer Manufacturers, designed to step up or step down voltage levels for efficient transmission and distribution of electricity within the grid.

Get a free quotePad Mounted Transformer

25 KVA-80000 KVA Pad Mounted Electrical Transformer Manufacturers is a ground-level electrical transformer widely utilized for power distribution in residential, commercial, and industrial settings.

Get a free quoteHot Electrical Transformer Manufacturers Pruducts

Pad Mounted Transformer

EverNew is a leading Electrical Transformer Manufacturers, specializing in high quality three phase pad mounted transformers with capacities up to 8000 KVA. Our transformers are widely used in industrial, commercial, and residential applications, offering exceptional efficiency, reliability, and safety. Designed for easy installation and maintenance, our compact and rugged transformers are built to provide a stable power supply in various environments.

As a trusted Electrical Transformer Manufacturers, our pad mounted transformers have UL, cUL, CSA and other certifications. We deliver more than 2,000 units to users around the world every year, especially users in North America, and have a good product reputation. Our pad mounted transformers are designed to be compact, rugged and easy to install and maintain. EverNew’s pad type transformers also have multiple safety protection functions, including overload protection, short-circuit protection and temperature protection, to ensure the safe operation of the equipment.

Visit our factory to discover high quality pad mounted transformers at factory wholesale prices.

Pole Mounted Transformer

EverNew Transformer is a china trusted Electrical Transformer Manufacturer offering pole mounted transformers from 10 kVA to 500 kVA. Our transformers are designed to meet international standards such as ANSI/IEEE, CSA, and DOE, ensuring compliance with the highest specifications. These transformers are widely used in the United States, Canada, and Argentina, providing reliable power distribution for industrial and public infrastructure, especially in remote rural areas. Our single phase pole mounted transformers are versatile and customizable to meet specific voltage and application requirements.

At EverNew Transformer, we prioritize quality and reliability. Each transformer undergoes strict testing to ensure it meets international standards, guaranteeing consistent performance and efficient power distribution. As a leading Electrical Transformer Manufacturers, we deliver durable and reliable solutions for all your power distribution needs across North and South America.

GET A FREE QUOTEDry Type Transformer

EverNew Transformer is top Electrical Transformer Manufacturers specializing in dry type transformers, offering standard products with rated capacities up to 10 MVA and voltages up to 35 kV. Our transformers are highly customizable to meet specific requirements, and their compact design ensures easy installation, making them the ideal solution for various industries. As a recognized manufacturer of cast resin transformers, our dry type models hold multiple certifications, including UL, cUL, and CSA, guaranteeing reliability and safety.

We also provide tailored solutions for renewable energy applications, including on load tap changing dry type transformers for solar photovoltaic systems. Our CSD shipboard dry type transformers are designed to meet the demanding requirements of the marine environment, delivering reliable power solutions for ships. EverNew three phase dry type transformers are widely used in sectors such as subways, ships, mines, chemical plants, power enterprises, and high density buildings with specific fire safety needs. As a trusted Electrical Transformer Manufacturers, we ensure that all our products meet international standards for safety, performance, and reliability.

Learn more about :Dry Type Transformer

GET A FREE QUOTESubstation Transformer

EverNew Transformer is a professional substation Electrical Transformer Manufacturers, offering transformers with rated voltages that can reach tens of kV or even higher. Our substation transformers are designed to meet the needs of power grid transmission, distribution, and large-scale industrial power consumption. Featuring a sealed structure and excellent insulation materials, they are built to adapt to various operating environments while meeting safety regulations worldwide.

With over 30 years of production and design experience, EverNew Transformer ensures that all products comply with IEEE C57, IEEE C57.12.50, and other international standards, including IEEE, IEC, ANSI, CSA, AS, and EN. As a leading China Electrical Transformer Manufacturers for sale, we operate multiple state of the art transformer factories, enabling us to quickly respond to customer needs with customized solutions. Our substation transformers are known for their high reliability, offering long-term stable operation while minimizing downtime and maintenance. This ensures the continuous and reliable power supply to the grid, making EverNew Transformer the preferred choice for power grid infrastructure worldwide.

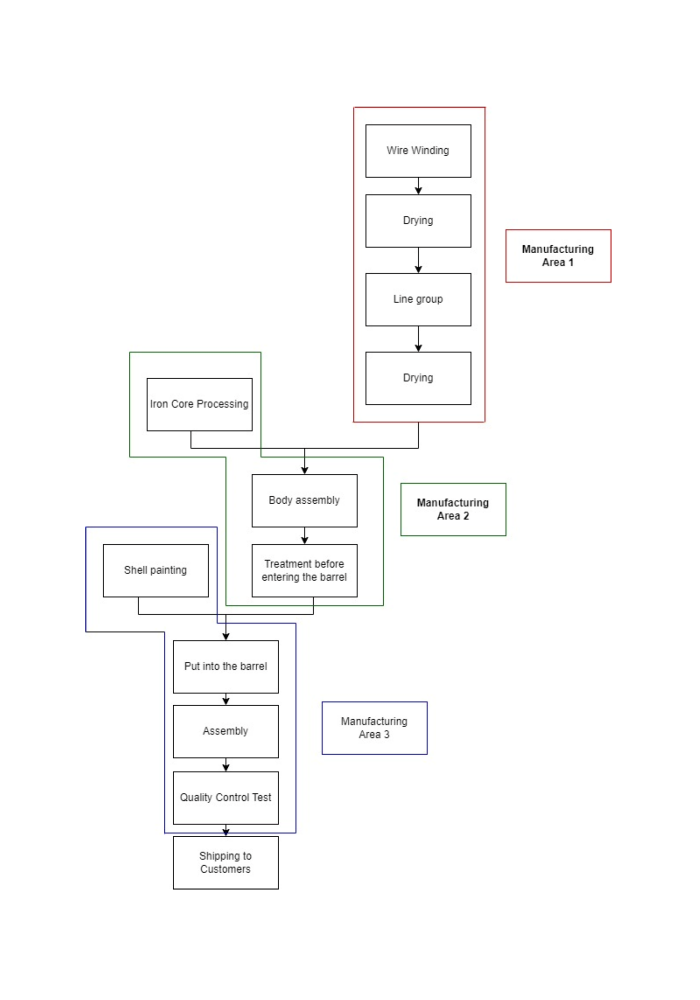

GET A FREE QUOTETransformer Manufacturing Process

Each step in production is vital to ensuring high quality transformers that meet performance, safety, and reliability standards. As a top China Electrical Transformer Manufacturers, EverNew Transformer delivers reliable, high performance solutions for global power and industrial needs.

- Design and Engineering: Determine transformer specifications and design parameters.

- Material Procurement: Source core materials, conductors, insulation, and components.

- Core Assembly: Stack silicon steel laminations to form the transformer core.

- Winding: Wind copper or aluminum conductors around the core to create primary and secondary windings.

- Insulation and Impregnation: Apply insulation materials and impregnate windings with oil or resin for insulation and protection.

- Assembly: Place windings into the transformer housing, add terminals, bushings, and cooling systems, and seal the transformer.

- Testing: Perform routine and type tests to ensure performance and safety standards are met.

- Finishing and Packaging: Apply finishing touches such as painting and labeling, and package the transformer for shipment.

Learn more about the various transformer production processes, welcome to our transformer factory in China and let the engineers introduce you in detail.

GET A FREE QUOTE

Get Your Custom Transformer

EverNew Transformer is best Electrical Transformer Manufacturers, producing various high quality electrical transformers for global clients. We offer customized solutions tailored to meet the unique power requirements of our customers. Below are your customized options.

Get A free quoteThe advantages of EverNew Transformer

As leading China Electrical Transformer Manufacturers, EverNew Transformer provides efficient, durable transformers. Our innovative designs cater to diverse needs, offering customized solutions and dedicated support for seamless integration and customer satisfaction.

- Innovative Design: EverNew Transformer offers transformers featuring cutting edge designs tailored to meet diverse voltage and power requirements, ensuring optimal performance.

- High Efficiency: Our transformers are engineered for maximum efficiency, minimizing energy losses during voltage transformation and distribution, leading to cost savings for our customers.

- Reliability and Durability: With stringent quality control measures and the use of premium materials, our transformers are built to last, providing reliable and durable solutions for various applications.

- Customization and Support: We prioritize customer satisfaction, offering tailored solutions and dedicated support to meet unique needs, ensuring seamless integration and operation of our transformers.

China Electrical Transformer Manufacturers R&D Capabilities

Electrical Transformer Manufacturers include the following:

- Strong R&D Team: With over 30 years of transformer design experience, we boast a robust R&D team well versed in international standards such as IEC, IEEE/ANSI, and CSA.

- Expert Technical Team: Our technical team, comprising electrical engineers and CAD draftsmen, ensures precision in design and execution.

- Cutting edge Technology: We utilize the latest technology and modern facilities to manufacture transformers that meet stringent quality standards.

- Quality Materials: EverNew transformer are crafted from qualified standard materials sourced through international procurement, meeting the highest industry benchmarks.

Our ability to deliver oil immersed transformers up to 500KV makes our design team stand out.learn more about the R&D capabilities of China Electrical Transformer Manufacturers, you are welcome to visit our Chinese factories.

GET A FREE QUOTETransformer Applications

As leading Electrical Transformer Manufacturers, Evernew Transformer sells a wide range of transformers to customers worldwide (including the United States, Canada, Australia, Brazil) at manufacturer factory prices.our products are essential for power distribution, industrial operations, renewable energy integration, and transportation. From stepping down high voltage for safe delivery to ensuring stable power supply in manufacturing, facilitating renewable energy integration, and powering electric vehicles and railways, transformers play a crucial role. Our versatile solutions contribute to efficient energy transmission, reliability, and sustainability across diverse applications.

Power Distribution

Transformers are vital in power distribution networks, stepping down high voltage from power plants for safe delivery to homes and businesses. They ensure efficient transmission over long distances, minimizing energy losses and providing a reliable supply of electricity to consumers. China Electrical Transformer Manufacturers, providing safe and reliable transformer power distribution

Industrial Applications

The industrial sector relies on transformers for voltage regulation, equipment isolation, and powering machinery. In manufacturing, transformers ensure stable power supply for consistent production. Learn more about industrial transformer applications from EverNew Transformer, a leading Chinese electrical transformer manufacturers.Contact Us Now

Renewable Energy Integration

Transformers play a crucial role in integrating renewable energy sources like wind and solar power into the grid by facilitating the conversion and transmission of fluctuating energy outputs, ensuring smooth integration with the existing power infrastructure.As Electrical Transformer Manufacturers, Evernew produces various new energy transformers

Transportation

EVs and railway systems require transformers for charging stations and traction purposes, respectively. Transformers enable the conversion of grid electricity to suitable voltages for charging EV batteries or powering electric locomotives, supporting the transition towards greener transportation solutions.China Electrical Transformer Manufactures, Evernew offers a variety of transportation transformer solutions

Why Choose Us as Your Transformer Supplier

Extensive Manufacturing Expertise

With decades of industry experience, we are seasoned professionals in transformer manufacturing. Our extensive knowledge and expertise ensure that each transformer we deliver is meticulously crafted, highly reliable, and meets the highest performance standards. We manufacture a wide range of transformers for customers around the world.

Cutting edge Research and Development

At the heart of our operation lies a dedicated team of engineers and researchers continually pushing the boundaries of transformer technology. We invest heavily in R&D to develop innovative solutions that optimize efficiency, enhance performance, and meet the evolving needs of our customers.

Competitive Factory Pricing

As China Leading Electrical Transformer Manufacturers, we pride ourselves on offering competitive factory prices without compromising on quality. By leveraging economies of scale and operational efficiencies, we provide cost-effective solutions tailored to your budgetary requirements, ensuring maximum value for your investment.

Stringent Quality Control Measures

Quality is ingrained in every aspect of our production process. From meticulous material selection to rigorous testing protocols, we enforce strict quality control measures to guarantee that each transformer leaving our facility meets the highest standards of reliability and durability. Your satisfaction and peace of mind are our top priorities.

Evernew Electrical Transformer Manufacturers Factory

What Our Other Customers Say About Us

Our Partner

Ready to get the perfect product?

Contact China Electrical Transformer Manufacturers now

Evernew Transformer provides professional free consultation

Transformers FAQs

Our transformers are designed with high efficiency ratings to minimize energy loss during operation, resulting in cost savings and reduced environmental impact.

Yes, we specialize in providing tailored transformer solutions to accommodate various voltage requirements, ensuring compatibility with your specific application.

Our transformers incorporate comprehensive safety features such as overload protection, short-circuit protection, and insulation systems to ensure safe and reliable operation in diverse environments.

Our transformers are built to withstand rigorous usage and are engineered for long-term reliability. With proper maintenance, they can provide years of dependable service.

Absolutely, we offer comprehensive after-sales support and technical assistance to address any inquiries or issues you may encounter with our transformers. Our team of experts is always available to assist you.

Yes, we provide all necessary documentation and certifications to ensure compliance with industry standards and regulations. Our transformers undergo rigorous testing and meet the highest quality standards for reliability and performance. UL/CUL certification CSA certification CESI certification CNAS certification SGS certification, UL/cUL certification, CE certification