Непрерывные транспонированные проводники (CTC) Эмалированный провод

Тип продукта: Непрерывные транспонированные проводники Эмалированный провод (CTC)

Материал проводника: Медь или алюминий

Тип проводника: Сплошной (прямоугольный проводник)

Материал изоляции: Эмалированная проволока (PEW, PIW, EIW, AIW и т.д.)

Материал покрытия: Бумага или хлопковая нить

Температурный рейтинг: 120°C

Применимые стандарты: IEC, NEMA, GB, JIS

Обзор продукции:

Эмалированный провод Continuous Transposed Conductors (CTC) является важным компонентом обмоток трансформаторов, реакторов и крупного силового электрооборудования. В качестве материала проводника CTC используется медь или алюминий, что обеспечивает превосходную электропроводность. Его уникальная структура "непрерывной транспозиции" эффективно снижает потери на вихревые токи, минимизирует циркуляционные потери, вызванные утечкой магнитного поля, и повышает эффективность и надежность оборудования. CTC широко используется в крупных масляные силовые трансформаторы, сухие трансформаторыи реакторах, особенно в устройствах, требующих высокой мощности, высокой эффективности и высокой стабильности.

Особенности продукта:

- Высокая эффективность: В проводниках CTC используется уникальная технология непрерывной транспозиции, которая значительно снижает потери на вихревые токи, минимизируя потери энергии и повышая общую эффективность трансформаторов и реакторов.

- Высокая механическая прочность: Высокопрочные медные или алюминиевые проводники в сочетании со специальной техникой оплетки повышают механическую прочность обмоток, позволяя им выдерживать высокие температуры и механические нагрузки.

- Отличные изоляционные характеристики: В эмалированном проводе CTC используются высококачественные эмалевые изоляционные материалы, обеспечивающие изоляцию проводника, предотвращающие короткие замыкания и потери электричества.

- Экономия места: Благодаря компактному расположению и транспозиционной конструкции CTC улучшает использование пространства для обмоток, уменьшая объем трансформатора и снижая затраты.

- Приспособленность к высоким температурам: Использование устойчивых к высоким температурам изоляционных материалов, таких как эмалированный провод на основе поливинилового спирта (ПВА), обеспечивает стабильную работу CTC при высоких температурах и подходит для работы в жестких условиях.

Читать далее:Эмалированный плоский медно-алюминиевый обмоточный провод для трансформаторов, промышленных двигателей и дросселей

Приложения:

- Большие масляные силовые трансформаторы: Идеально подходящий для систем передачи и распределения электроэнергии, CTC эффективно снижает потери и повышает энергоэффективность высоковольтных и мощных трансформаторов.

- Реакторы: КТК широко используется в обмотках реакторов в энергосистемах, помогая контролировать колебания тока и напряжения, тем самым повышая стабильность системы.

- Сухие трансформаторы: CTC подходит для сухих трансформаторов большой мощности, где его превосходные теплоотводящие свойства повышают эффективность работы и продлевают срок службы оборудования.

- Большие индукторы: В различном энергетическом оборудовании CTC снижает потери и повышает стабильность системы, удовлетворяя потребности в высокой производительности.

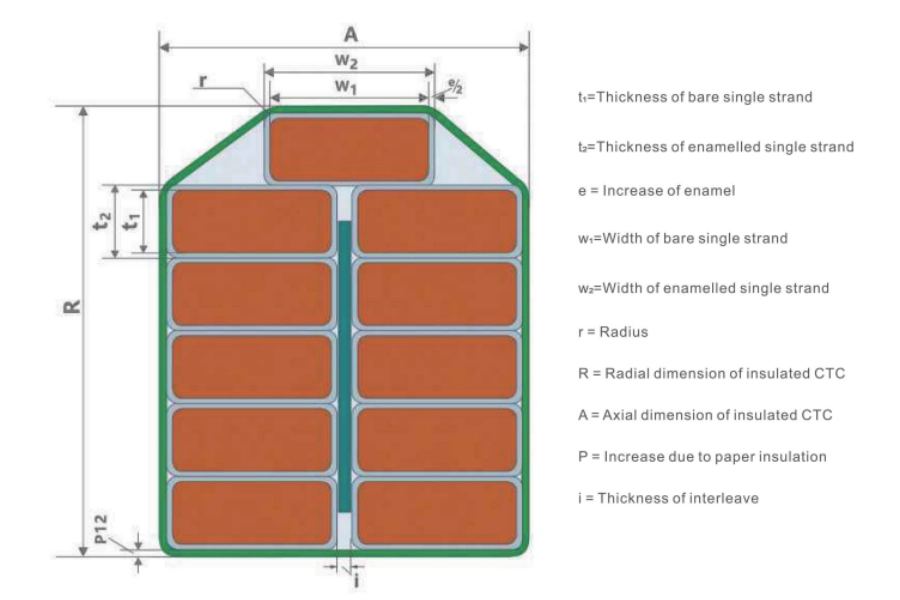

Технические характеристики:

- Материал проводника: Медь или алюминий

- Размеры проводника:

- Толщина отдельных проводников: 0,90-3,15 мм (допуск ±0,01 мм)

- Ширина отдельных проводников: 2,50-13,00 мм (допуск ±0,01 мм)

- Соотношение ширины и высоты: 2,0 < b/a < 9,0

- Материал изоляции: PEW, PIW, EIW, AIW и т.д.

- Материал покрытия: Бумага или хлопковая нить

- Максимальные внешние размеры: Высота: 120 мм, ширина: 26 мм (Допуск ±0,05 мм)

- Количество нитей КТК: 5-80 нитей (можно четные или нечетные)

- Температурный рейтинг: 120°C

- Стандарты: IEC, NEMA, GB, JIS

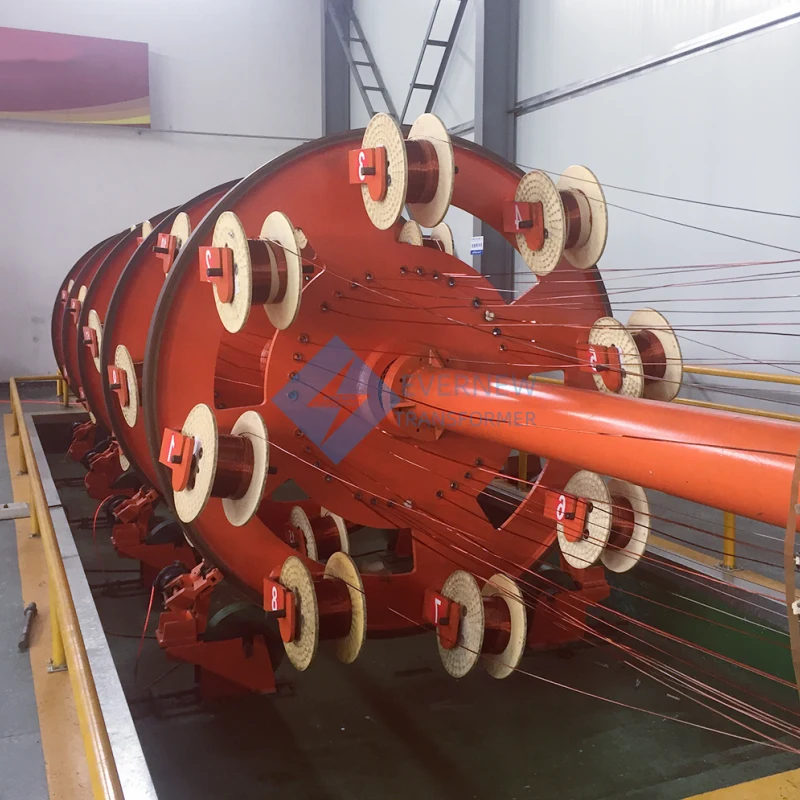

Процесс производства:

Проводники CTC изготавливаются с использованием передовых технологий производства, включая точную подготовку проводов, намотку, транспозицию, нанесение покрытия и формовку. Сначала медные или алюминиевые проводники нарезаются и покрываются эмалевой изоляцией. Затем провода располагаются и укладываются в соответствии с определенной схемой транспозиции, что обеспечивает сходство электромагнитной обстановки для каждого провода и минимизацию вихревых и циркуляционных потерь. Наконец, пучки проводов связываются вместе и подвергаются дополнительной изоляционной обработке для обеспечения безопасной работы в условиях высокого напряжения.

Контроль качества и тестирование:

- Электрические испытания: Включает в себя тестирование сопротивления, изоляции и проверку целостности электропроводки, чтобы убедиться, что продукт соответствует спецификациям по проводимости и изоляции.

- Испытание механических характеристик: Испытания включают прочность на разрыв, гибкость и механическую стабильность, чтобы убедиться, что продукт выдерживает механические нагрузки, возникающие при работе силового оборудования.

- Тестирование тепловых характеристик: Обеспечивает сохранение хороших характеристик CTC при длительной работе при высоких температурах, что делает его пригодным для использования в высокотемпературных средах трансформаторов и реакторов.

Преимущества:

- Сокращение потерь: Транспозиционная конструкция проводников CTC значительно снижает вихревые токи и циркуляционные потери, вызванные утечкой магнитного поля.

- Повышенная надежность: Высокая механическая прочность и изоляционные характеристики позволяют использовать CTC в сложных условиях эксплуатации, продлевая срок службы оборудования.

- Экономия места и средств: Компактная конструкция улучшает использование пространства для обмоток, уменьшает размеры трансформатора и снижает производственные и транспортные расходы.

- Улучшенные характеристики охлаждения: Превосходные теплопроводные и рассеивающие свойства помогают добиться эффективного охлаждения обмоток трансформатора.

Заключение:

Эмалированный провод Continuous Transposed Conductors (CTC) - это высокоэффективный материал для обмоток трансформаторов с широкими перспективами применения. Его эффективные электрические характеристики, выдающаяся механическая прочность и отличные изоляционные свойства делают его незаменимым компонентом сердечника в высоковольтных трансформаторах, реакторах и другом силовом оборудовании. Если вам нужны индивидуальные проводники CTC, отвечающие конкретным требованиям, не стесняйтесь обращаться к нам. Мы предоставим вам высококачественную продукцию и профессиональную техническую поддержку.

Отзывы

Отзывов пока нет.