Transformer conservators are essential components in oil-immersed power transformers, acting as vital mechanisms for thermal oil volume regulation and atmospheric isolation. By preventing contamination, oxidation, and moisture ingress, conservators significantly extend the life and reliability of the transformer. This guide explores their function, structure, different types, sealing techniques, and their role in maintaining transformer efficiency and operational safety.

1. What Is a Transformer Conservator?

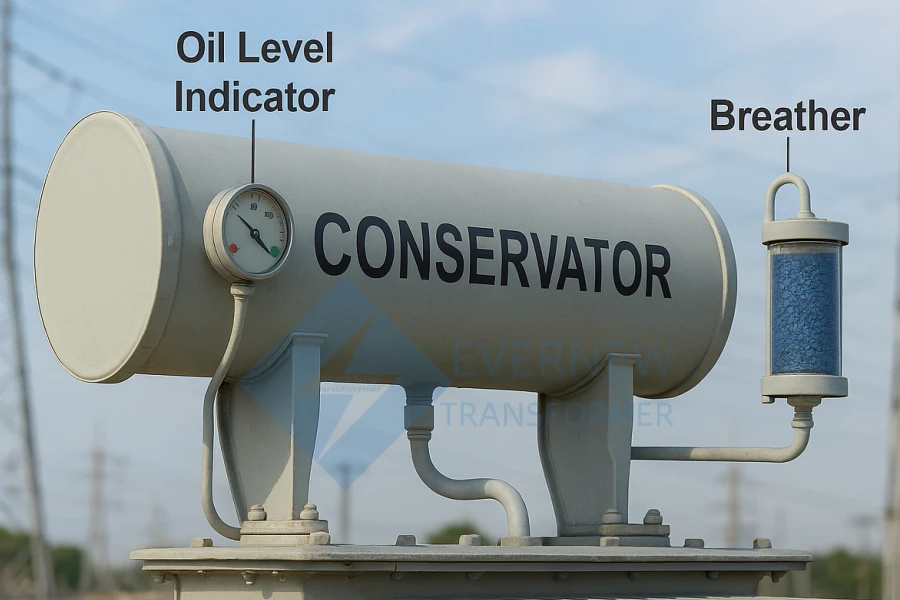

A transformer conservator, also known as a transformer oil conservator tank or expansion tank, is an auxiliary chamber mounted above the transformer’s main tank. It allows the insulating oil inside the transformer to expand and contract due to temperature changes without exposing it to ambient air, thus maintaining oil quality and dielectric strength.

2. Why Are Conservators Critical for Transformer Performance?

The conservator system performs several key functions:

Manages oil volume changes due to temperature variations

Prevents contact with external air, reducing moisture absorption and oxidation

Maintains pressure balance inside the transformer tank

Protects insulating oil quality, ensuring long-term dielectric performance

Supports unattended operation in modern power grids

Enables accurate oil level monitoring and proactive maintenance

By doing so, it helps maximize transformer service life and minimizes the risk of insulation failure.

3. Key Components of a Transformer Conservator System

A standard conservator assembly typically includes:

Conservator tank: The main reservoir for oil expansion/contraction

Flexible separator (bladder or diaphragm): Prevents contact between oil and air

Breather (with silica gel): Absorbs moisture from incoming air

Oil level indicator: Monitors oil levels for operational safety

Relief valve or pressure damper: Manages pressure surges due to rapid thermal changes

Buchholz relay (optional): Detects gas accumulation in fault conditions

4. Types of Transformer Conservators

4.1 Corrugated Type Conservator (Metal Expander)

This is the most advanced and widely adopted type in modern sealed transformers.

Structure & Operation:

Uses metal bellows or corrugated stainless-steel pipes as expansion chambers.

Fully sealed from atmosphere.

Compensates oil volume by mechanical expansion/contraction of the metal.

Subtypes:

Internal Oil Corrugated Conservator (vertical): Higher performance but larger volume.

External Oil Corrugated Conservator (horizontal): Compact, good heat dissipation.

Advantages:

Excellent sealing; no moisture ingress

Long lifespan (>20,000 expansion cycles)

Accurate oil level detection without false readings

Built-in pressure damper enhances safety

Lower maintenance; ideal for remote or unmanned stations

4.2 Capsule Type Conservator

An older design using an oil-resistant rubber or nylon bladder (capsule) inside the conservator tank.

Operation:

The capsule expands/contracts with oil level.

Air flows through a breather to maintain pressure equilibrium.

Challenges:

Capsule aging and cracking are common

Poor long-term sealing performance

Infiltration of moisture and air leads to oil degradation

Decreasing in usage due to reliability concerns

4.3 Diaphragm Type Conservator

This design uses a flexible diaphragm (rubber or synthetic layers) to separate air from oil.

Construction:

Multi-layered material (e.g., nylon cloth + neoprene + cyanogen butadiene)

Provides a barrier between oil and air

Limitations:

Sensitive to installation quality and material wear

High probability of oil leakage or diaphragm rupture

Decreased safety in long-term operations

Gradually being phased out in favor of corrugated designs

4.4 Open-Type Conservator

The oldest and most basic design, directly exposing oil to ambient air.

Major Drawbacks:

Rapid oil oxidation and moisture absorption

Severe degradation of insulating oil

High risk of internal faults and shortened transformer life

Now obsolete for medium/high-voltage applications

5. Sealing Mechanisms of Transformer Conservators

Proper sealing is essential to protect transformer oil from atmospheric exposure.

a. Open Conservator (Unsealed)

Direct contact with air

Oil oxidizes quickly; moisture ingress is common

Only used in low-voltage or outdated transformers

b. Capsule Type (Partial Seal)

Air separated via bladder

Prone to bladder fatigue and cracking

Requires frequent monitoring and maintenance

c. Diaphragm Type (Improved Seal)

Better sealing than capsule, but material aging remains a problem

Sensitive to installation and maintenance quality

d. Corrugated Type (Full Seal)

Best-in-class sealing

No false oil levels

No air contact; low maintenance

Withstands temperature and pressure cycles reliably

6. Temperature Changes and Volume Compensation

Insulating oil expands when heated and contracts when cooled. A conservator must:

Absorb oil expansion without creating pressure spikes

Provide vacuum compensation during cooling

Prevent air from entering the main tank

Avoid oil overflow or vacuum-induced deformation

Corrugated types respond automatically to thermal changes by adjusting the bellows’ volume — providing real-time compensation and maintaining system equilibrium.

7. Conservator’s Role in Transformer Reliability

A well-designed conservator enhances transformer performance by:

Maintaining consistent oil quality

Preventing electrical breakdown due to moisture or gas bubbles

Minimizing oil oxidation and acid formation

Protecting the core and windings from premature aging

Reducing downtime and unplanned maintenance

Supporting long-term grid reliability and stability

8. Monitoring and Maintenance

Routine inspection and predictive maintenance are essential for optimal performance.

Tasks include:

Checking oil levels via indicator windows or sensors

Replacing silica gel in breathers

Inspecting bladders/diaphragms for wear or damage

Testing alarm switches for oil level thresholds

Ensuring no oil leakage from connections or valves

Corrugated sealed designs typically require the least intervention, making them ideal for modern utilities.

9. Application Notes: On-Load Tap Changer Consideration

Avoid using fully sealed metal corrugated conservators on on-load tap changer (OLTC) tanks, as gas generated during tap operations can accumulate and impair operation. OLTC conservators require ventilation and gas release mechanisms not suited to sealed bellows designs.

10. Conclusion: Choosing the Right Conservator

Choosing the appropriate conservator depends on:

Transformer voltage and capacity

Environmental conditions (humidity, temperature range)

Maintenance accessibility

Operational criticality

Expected service life and cost of ownership

For most modern applications, metal corrugated (sealed) conservators are the preferred solution — combining reliability, safety, and reduced maintenance.