What Is MVA Rating in Transformers?

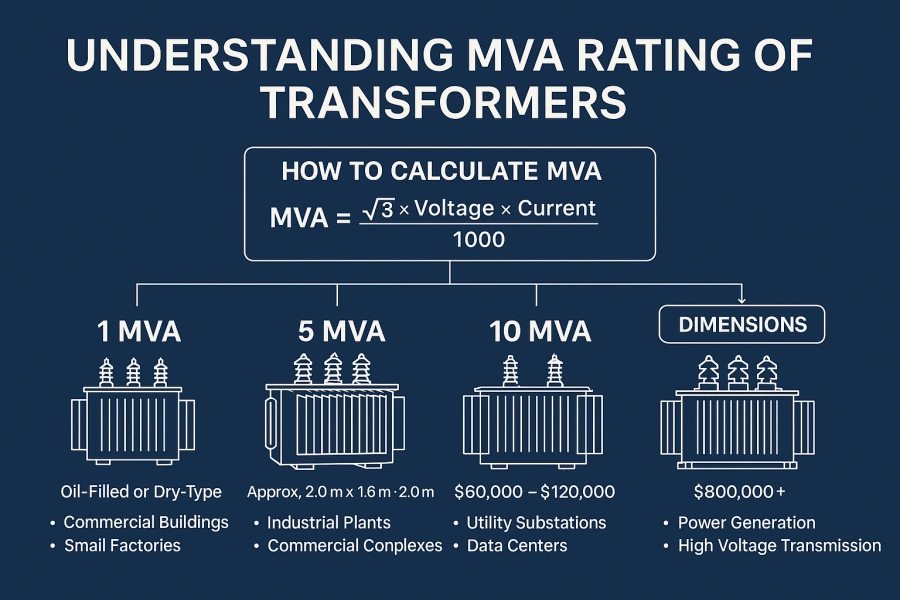

MVA, or Mega Volt-Amps, is a unit of apparent power used to define the capacity of a transformer. Unlike kVA (kilo Volt-Amps), which is used for smaller units, MVA is commonly used for medium and large power transformers.

The MVA rating of a transformer indicates the maximum load it can handle without overheating or sustaining damage, under standard operating conditions.

How to Calculate MVA Rating of a Transformer

The formula to calculate the MVA rating is:

MVA = (√3 × Line Voltage (kV) × Line Current (A)) / 1000

For single-phase transformers, the formula is:

MVA = (Voltage (kV) × Current (A)) / 1000

This calculation helps ensure correct transformer sizing for industrial, commercial, or utility-scale applications.

What Affects Transformer Size and MVA Rating?

The physical size and MVA (Mega Volt-Ampere) rating of a transformer are determined by a combination of electrical, thermal, mechanical, and environmental factors. Understanding these parameters is crucial for proper transformer selection, performance, longevity, and safety in residential, commercial, or industrial applications.

✅ Key Factors Influencing Transformer Size and Rating:

🔹 1. Voltage Levels (Primary & Secondary)

The input (primary) and output (secondary) voltage determine the number of winding turns and insulation requirements.

Higher voltages require more insulation and larger clearance.

Common voltage levels: 11kV, 33kV, 66kV, 110kV, 220kV, and up to 500kV.

🔹 2. Current Capacity

The amount of current the transformer must handle determines the cross-sectional area of the conductors.

Larger current = thicker winding = increased size

Also affects temperature rise and copper losses

🔹 3. MVA Rating (Apparent Power)

The total power-handling capacity of the transformer, measured in MVA, impacts the core size, conductor volume, and cooling needs.

1 MVA = 1,000 kVA

Higher MVA = larger transformer footprint and tank size

Read More:What is a Kva Transformer

🔹 4. System Frequency (50Hz or 60Hz)

The frequency of the power system affects the size of the magnetic core.

60Hz systems (North America) may use slightly smaller cores than 50Hz systems (Europe, Asia)

Affects magnetic flux density and iron losses

🔹 5. Ambient Temperature

Environmental temperature directly influences the cooling requirement and insulation aging.

Transformers in hot climates (e.g., Mexico, Brazil) require enhanced ventilation or derating

Installation in cold or alpine zones requires freeze protection and cold-start considerations

🔹 6. Cooling Method

The selected cooling technique determines the size and complexity of radiators, fans, and oil pumps.

ONAN (Oil Natural Air Natural) – passive cooling, used for ≤10 MVA

ONAF (Oil Natural Air Forced) – adds fans for better heat dissipation

OFAF (Oil Forced Air Forced) – active system for high MVA, e.g., 50 MVA–500 MVA units

🔹 7. Impedance & Efficiency Requirements

Transformers with low impedance allow better voltage regulation but require thicker windings.

High efficiency (98–99%) requires high-grade core materials and design precision

Impacts cost, volume, and material selection

🔹 8. Installation Environment

Where the transformer is installed significantly affects its size and design:

Indoor units require compact footprint and dry-type design

Outdoor units need weather-resistant enclosures, corrosion protection (marine-grade coating for coastal zones)

Desert or coastal regions (e.g., Peru, Chile, Guyana) require dust, sand, or salt-fog protection

🛠 Design Trade-offs

Engineers must balance between compact design, thermal performance, material cost, mechanical strength, and maintainability. That’s why custom transformer sizing is often essential for large industrial and utility-scale projects.

2. Transformer Size Explained

Transformer size refers to the physical dimensions and total weight of the unit, which are directly proportional to its MVA rating. As the required power capacity increases, the transformer must incorporate larger internal components, higher insulation levels, and more advanced cooling systems, all of which contribute to an increase in physical size and mass.

🔧 What Determines Transformer Size?

Several internal design factors scale with MVA rating:

Core size: A larger magnetic core is needed to prevent saturation at high power.

Winding dimensions: Higher current requires thicker conductors and more copper or aluminum.

Cooling system: Larger MVA units generate more heat, requiring bigger radiators, fans, or oil circulation systems.

Insulation volume: To manage higher voltages and prevent breakdowns, more space and material are used.

Structural components: Tanks, base frames, and bushings become heavier and more robust.

📦 Approximate Sizes by MVA Rating

| MVA Rating | Estimated Weight | Typical Dimensions (L x W x H) | Cooling Type |

|---|---|---|---|

| 1 MVA | ~2 tons (1,800–2,200 kg) | ~1.5m × 1.1m × 1.5m | ONAN |

| 5 MVA | ~6–8 tons | ~2.5m × 2m × 2.2m | ONAN / ONAF |

| 10 MVA | ~12–15 tons | ~3.5m × 2.5m × 2.5m | ONAF |

| 100 MVA | 90–120+ tons | ~6.5m × 4m × 4.5m | OFAF / Water-Cooled |

🛠 Note: Actual dimensions vary depending on voltage class (e.g., 11kV, 33kV, 132kV), cooling design, and specific application.

🌍 Real-World Examples

A 1 MVA transformer is commonly used in small industrial or residential power systems. It’s compact and typically dry-type or ONAN-cooled.

A 5 MVA transformer is often found in medium-sized commercial facilities, industrial plants, or utility distribution systems.

A 10 MVA transformer supports large factories or substation-level loads, requiring more active cooling.

A 100 MVA transformer is used in high-voltage substations and utility transmission systems. It’s a massive unit requiring heavy-duty transport and site-specific installation.

Learn More:220 kv 230kv High Voltage Special Oil Immersed Power Transformer

🌍 Work With a Global Transformer Leader

Whether you need a 1 MVA, 10 MVA, or 100 MVA transformer, EVERNEW Transformer is a trusted manufacturer and supplier, offering:

OEM & ODM solutions

Global delivery & support

Certifications: IEC, ANSI, UL, ISO

Applications: Utilities, industry, renewable energy

Markets served: USA, Canada, Mexico, Brazil, Argentina, Guyana, Chile, Bolivia, Jamaica, Spain, and more

🔍 Transformer Sizing & MVA Rating – FAQ

❓What is the formula to calculate MVA for a 3-phase transformer?

Answer:

MVA = (√3 × Line Voltage (kV) × Line Current (A)) / 1000

This formula is commonly used to size power transformers in industrial and utility applications.

❓How do I calculate MVA for a single-phase transformer?

Answer:

MVA = (Line Voltage (kV) × Line Current (A)) / 1000

This applies to residential and light commercial transformers.

❓How do I convert kVA to MVA?

Answer:

MVA = kVA / 1000

For example, 5000 kVA = 5 MVA.

❓How do I convert MVA to kVA?

Answer:

kVA = MVA × 1000

For instance, 10 MVA = 10,000 kVA.

❓How do I calculate voltage if I know the kVA and current?

Answer:

Voltage (V) = (kVA × 1000) / Current (A)

This is helpful when estimating voltage needs during transformer selection.

❓How do I calculate kVA for a 3-phase electrical system?

Answer:

kVA = (√3 × Voltage (V) × Current (A)) / 1000

This is the standard formula for most 3-phase transformer loads.

❓How can I determine the secondary voltage using the turn ratio?

Answer:

V₂ = (T₂ × V₁) / T₁

Where:

V₁ = Primary Voltage

T₁ = Primary Turns

T₂ = Secondary Turns

V₂ = Secondary Voltage

❓How can I find the primary voltage if I know the current ratio?

Answer:

V₁ = (V₂ × I₂) / I₁

Where:

I₁ = Primary Current

I₂ = Secondary Current

V₂ = Secondary Voltage

V₁ = Primary Voltage