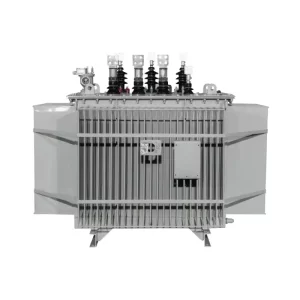

2500 KVA three phase oil immersed distribution transformer is a high-efficiency and high-reliability power equipment, widely used in various distribution systems. It converts high-voltage electric energy into low-voltage electric energy through the principle of electromagnetic induction to meet different power needs. This 2500 KVA transformer is manufactured with high-quality materials and advanced technology, with excellent performance and long service life.

More Evernew Transformer:2000 KVA 33KV Oil Type Power Distribution Transformer

Main Features of 2500 KVA Transformer

High Efficiency and Energy Saving, Low Loss

No-load Loss: ≤ 0.1% (relative to rated power)

Load Loss: ≤ 0.5% (relative to rated power)

Energy Efficiency Level: Meets the Level 1 energy efficiency standard of GB20052-2013

Strong Overload Capability

Overload Capacity: Can operate at 120% of rated load for 2 hours without cooling

Short-circuit Voltage: 6% ± 0.5%

Stable Operation and Low Noise

Noise Level: ≤ 45 dB(A)

Operating Temperature Rise: ≤ 65°C (relative to ambient temperature)

Vibration Coefficient: ≤ 2.5 mm/s

Compact Structure, Easy to Install and Maintain

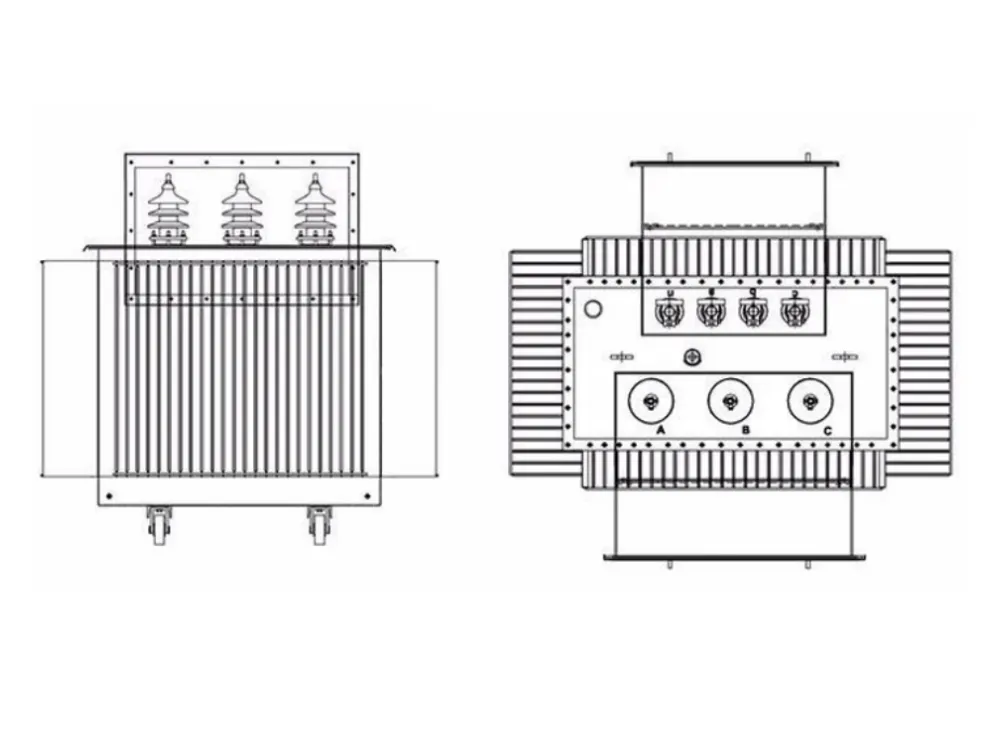

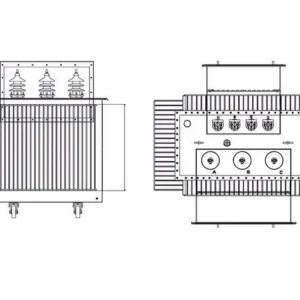

Dimensions: Length × Width × Height (specific dimensions vary by model)

Weight: 300 kg – 2000 kg (varies by model)

Cooling Method: Natural air cooling/forced air cooling (customizable based on requirements)

2500 KVA Transformer Application

The 2500 KVA three phase oil filled distribution transformer finds extensive application across various sectors such as industrial, commercial, public utilities, and agriculture. It provides stable and efficient power support to different users, promoting stable development across various industries.

Case in Point: A Large Hospital in Mendoza, Argentina

A large hospital in Mendoza, Argentina, needs to ensure a stable power supply for its various medical equipment and facilities to avoid any interruptions that could affect patient care. By choosing the 2500 KVA three phase oil filled distribution transformer, the hospital guarantees a stable power supply.

Implementation:

- Strategic Placement: The transformer is strategically installed in the hospital’s power center with emergency power switching devices.

- Cooling System: A forced air cooling system is employed to ensure reliable operation under any circumstances.

This setup enhances the hospital’s service quality by providing a consistent and reliable power supply, ensuring that all medical equipment functions optimally without power-related disruptions.

This transformer’s versatile applications and reliable performance make it an ideal choice for various sectors, contributing significantly to the stable development of industries.

Contact Evernew Transformer now to learn more about transformer applications

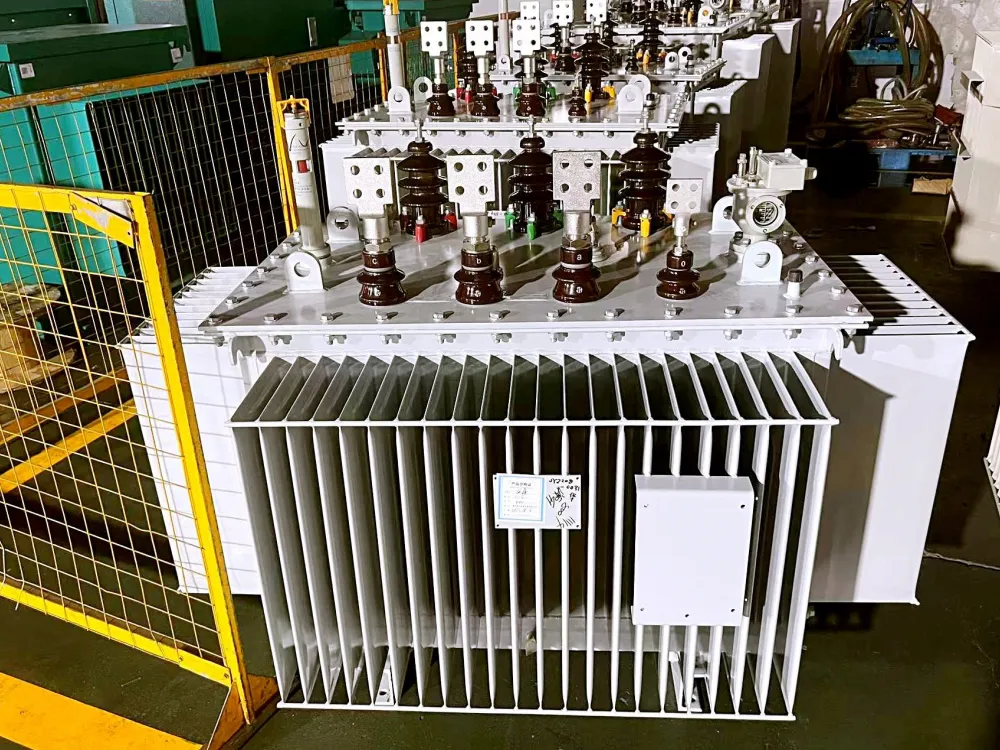

Accessories for 2500 KVA Three Phase Oil Filled Distribution Transformer

Evernew 2500 KVA three phase oil filled distribution transformer is equipped with several essential accessories to ensure its optimal performance, safety, and longevity. These accessories help in monitoring, controlling, and protecting the transformer under various operational conditions. Here are some of the key accessories:

Conservator Tank:

- Function: Maintains the oil level in the transformer and allows for oil expansion and contraction due to temperature changes.

- Features: Fitted with a breather to filter out moisture and dust from the air entering the conservator.

Breather:

- Function: Prevents moisture from entering the transformer oil by using silica gel.

- Features: Silica gel changes color as it absorbs moisture, indicating when it needs replacement.

Buchholz Relay:

- Function: Detects gas accumulation and sudden oil flow in the transformer, indicating internal faults.

- Features: Provides an alarm and trips the transformer to prevent damage.

Oil Temperature Indicator (OTI):

- Function: Monitors the temperature of the transformer oil.

- Features: Equipped with alarm and trip contacts to signal overheating.

Winding Temperature Indicator (WTI):

- Function: Measures the temperature of the transformer windings.

- Features: Comes with alarm and trip contacts for over-temperature protection.

Pressure Relief Device:

- Function: Releases excess pressure inside the transformer to prevent explosion.

- Features: Automatically operates when internal pressure exceeds safe limits.

Radiators or Cooling Fins:

- Function: Enhance the cooling of the transformer by increasing the surface area for heat dissipation.

- Features: Can be naturally or forced-cooled, depending on the design.

Oil Level Indicator:

- Function: Shows the oil level in the conservator tank.

- Features: Helps in maintaining the correct oil level for efficient transformer operation.

Tap Changer:

- Function: Allows adjustment of the transformer’s output voltage.

- Types: Can be on-load or off-load tap changers, depending on the requirement.

Magnetic Oil Level Gauge:

- Function: Provides a visual indication of the oil level inside the transformer.

- Features: Ensures that the oil level remains within the safe operating range.

Read More:Optimizing Power Distribution with Medium Voltage Transformer: The Ultimate Guide

Drain Valve:

- Function: Facilitates the removal of transformer oil for maintenance or replacement.

- Features: Usually located at the bottom of the transformer tank.

Oil Sampling Valve:

- Function: Allows for the extraction of oil samples to test for quality and contamination.

- Features: Essential for regular maintenance and condition monitoring.

Earthing Terminals:

- Function: Provide a secure connection to the ground for safety.

- Features: Ensure the transformer is properly earthed to prevent electrical hazards.

Cooling Fans (for forced cooling):

- Function: Provide additional cooling by blowing air over the radiators.

- Features: Controlled by thermostats to operate when the transformer temperature rises.

Surge Arresters:

- Function: Protect the transformer from voltage surges and lightning strikes.

- Features: Installed on both high and low voltage sides.

Terminal Bushings:

- Function: Provide insulated connections for the transformer’s input and output terminals.

- Features: Made from high-quality porcelain or composite materials.

These accessories play crucial roles in ensuring the safe and efficient operation of the 2500 KVA distribution transformer, making it reliable for various applications.

Learn More: Distribution Transformer:2024 Best Comprehensive Guide

Warranty period and service life of 2500 KVA transformer

1. Warranty Period

- Typical warranty period: 2500 KVA transformer are typically covered by a 2 year warranty, depending on the terms of the contract under which the Evernew transformer was purchased. Extended warranties are available, typically covering major components and fault resolution services.

2. Service Life

- Average Service Life: The average service life of a 2500 KVA transformer is 25 to 40 years. The actual service life depends on several factors, including:

- Environmental Conditions: Such as temperature, humidity, and pollution levels.

- Maintenance: Regular inspection and maintenance can significantly extend the transformer’s service life.

- Load Conditions: Operating the transformer under overload conditions can shorten its lifespan.

- Installation Quality: Professional installation and correct operation are crucial for prolonging the service life.

Following transformer maintenance recommendations will help maximize the life of your transformer and ensure it operates efficiently.

Learn More: What is a 3 phase pad mounted transformer

2500 KVA Three Phase oil Filled Distribution Transformer Price

Core Types: Amorphous Alloy vs. Silicon Steel

- Amorphous Alloy Cores: These cores offer lower losses and higher efficiency but are more expensive and noisier.

- Silicon Steel Cores: More cost-effective but with higher losses, making them a popular choice.

Winding Materials: Copper vs. Aluminum

- Copper Windings: Superior conductivity and durability but costlier. A 2500 KVA transformer with copper windings is about 15% more expensive.

- Aluminum Windings: More affordable but with lower conductivity.

Accessories

- International Brand Accessories: Brands like ABB, Schneider, and Qualitrol significantly increase costs, potentially by 50% or more.

- Local Brand Accessories: China’s strong supply chain advantages, high-quality, competitively priced accessories and transformer finished products

Efficiency Standards

- DOE 2016 Compliance: Transformers meeting these efficiency standards are more costly but offer reduced losses and higher performance, increasing costs by at least 30%.

The price of a 2500 KVA oil immersed three phase transformer is influenced by core type (amorphous alloy or silicon steel), winding material (copper or aluminum), accessory brand (international or local), and compliance with efficiency standards (like DOE 2016). For tailored advice, consult with Evernew transformer specialists based on your specific needs and budget.

2500 KVA Transformer Technical specifications

2500 KVA Three Phase Oil Filled Distribution Transformer Specification and Data Sheet

| Place of Origin | China |

|---|---|

| Brand Name | EverNew Transformer |

| Model Number | Oil immersed transformer |

| Number of Phase | Three Phase |

| Coil Number | Three |

| Winding Type | Multi-winding Transformer |

| Standard | IEC ANSI IEEE CCC |

| Shape of Core | Ring |

| Usage | Power Transformer |

| Rated Capacity | 2500 KVA |

| High Voltage | 35kV |

| Low Voltage | 380v/400v/415v/440v |

| Tapping Range | ±2×2.5% |

| Impedance Voltage | 0.04 |

| Load Loss | 2.73/2.6kW |

| No-load Loss | 2560 |

| No-load Current | 0.6 |

| Frequency | 50Hz/60Hz |

| Connection Group | Dyn11/Yyn0/Yd11/YNd11 |

| Cooling Method | ONAN |

| Coil Material | 100%Copper |

| Winding Material | CopperAluminum |

المراجعات

لا توجد مراجعات بعد.